Almost 90 per cent of the coal-based capacity in India uses indigenous coal, which is of low grade with an ash content of 30-45 per cent compared to imported coal, which has a lower ash content of 10-15 per cent. Coal-based power stations in the country generate a large quantity of ash, which not only requires large area of precious land for its disposal but is also one of the sources of both air and water pollution.

In the first half of 2018-19, about 93 million tonnes (mt) of fly ash was generated (by 156 thermal power plants [TPPs]) compared to 84 mt of fly ash generated (by 138 TPPs) during the same period in 2017-18 as per the Central Electricity Authority (CEA). The overall ash utilisation rate improved to around 68 per cent in the first half of 2018-19 from 60 per cent in 2017-18, but this was much lower than the ash utilisation target of 100 per cent specified under the CEA guidelines.

Power Line takes a look at the key trends in fly ash generation and its utilisation…

Policy directives for ash utilisation

The Ministry of Environment, Forest and Climate Change (MoEFCC) issued the first directive in September 1999 for promoting fly ash utilisation in the country, which has been amended from time to time. In the last amendment, notified in January 2016, the ministry mandated 100 per cent fly ash utilisation by TPPs by the end of December 2017. In addition, it was specified that power plant developers will bear the entire cost of ash transportation up to a 100 km radius. For distances of more than 100 km and up to 300 km, the developer will share the cost of ash transportation equally with the user or construction agency. Further, it directed TPPs to set up or assist in setting up manufacturing facilities for ash-based products on their premises so as to minimise the transportation of fly ash. The notification also suggested making use of fly ash-based products for all government schemes such as the Pradhan Mantri Gram Sadak Yojana, the Mahatma Gandhi National Rural Employment Guarantee Scheme and the Swachh Bharat Abhiyan. It advised the Ministry of Agriculture and Farmers’ Welfare to consider using fly ash as a soil conditioner.

In February 2018, the Ministry of Power launched a web-based application called Ash Track, aimed at enabling better ash management by providing an interface between fly ash producers (TPPs) and potential ash users such as road contractors and cement plants. The app gives information about fly ash producers and prospective users in each area as well as on ash availability. It allows users to apply online for fly ash procurement.

Despite various efforts and mandates by the government, the majority of TPPs have not been able to comply with the 100 per cent fly ash disposal target. The states sought time extension of two to five years to meet the 100 per cent utilisation target. However, their request was rejected by the National Green Tribunal (NGT) as any extension in time would have conflicted with the mandate under the Environment (Protection) Act, 1986, particularly when such an extension could harm the environment. Through an order dated November 20, 2018, the tribunal further imposed penalties ranging from Rs 10 million to Rs 50 million (depending on the capacity) on TPPs as the cost of damage to the environment. The NGT’s order is significant as it makes it legally binding for all TPPs to ensure the complete disposal of or utilisation of fly ash immediately. The tribunal further called for the constitution of a joint committee comprising representatives from the MoEFCC, the Central Pollution Control Board, the Indian Institute of Technology-Roorkee and other members to finalise an action plan covering aspects related to 100 per cent fly ash utilisation as well as its scientific and environmentally sound disposal.

Trends in fly ash generation and utilisation

Trends in fly ash generation and utilisation

In the first half of 2018-19, fly ash generation across 156 TPPs (aggregating 159 GW of capacity) stood at 93.26 mt, of which around 64.08 mt was utilised. The fly ash utilisation rate improved by 8 percentage points in the first half of 2018-19 as compared to the first half of 2017-18, when around 51 mt of the total 84 mt fly ash was utilised.

Further, of the 156 TPPs, 54 TPPs recorded 100 per cent or more fly ash utilisation. State genco GSECL’s Gandhinagar power station recorded the highest ash utilisation level in the country at 227 per cent. About 22 TPPs recorded fly ash utilisation of 90-100 per cent, 22 recorded 70-90 per cent utilisation, 21 recorded 50-70 per cent, and 29 recorded less than 50 per cent. Meanwhile, eight TPPs did not generate any ash during the year.

State-wise, seven states generated over 7 mt of fly ash each during the first half of the year 2018-19. These were Andhra Pradesh, Chhattisgarh, Madhya Pradesh, Maharashtra, Odisha, Uttar Pradesh and West Bengal. Chhattisgarh recorded the highest fly ash generation at 13 mt. Meanwhile, Gujarat, Punjab and Rajasthan achieved fly ash utilisation levels of over 100 per cent (Punjab reported the highest utilisation at 116.95 per cent). Further, Assam, Bihar and Madhya Pradesh utilised less than 50 per cent of the fly ash generated.

Utility-wise, of the 83 utilities for which the CEA received data, 29 utilities achieved a fly ash utilisation level of 100 per cent or more. Another 17 power utilities achieved fly ash utilisation in the range of 90-100 per cent. The ash utilisation level of the country’s largest power utility, NTPC Limited, stood at 53.3 per cent.

Modes of ash utilisation

Modes of ash utilisation

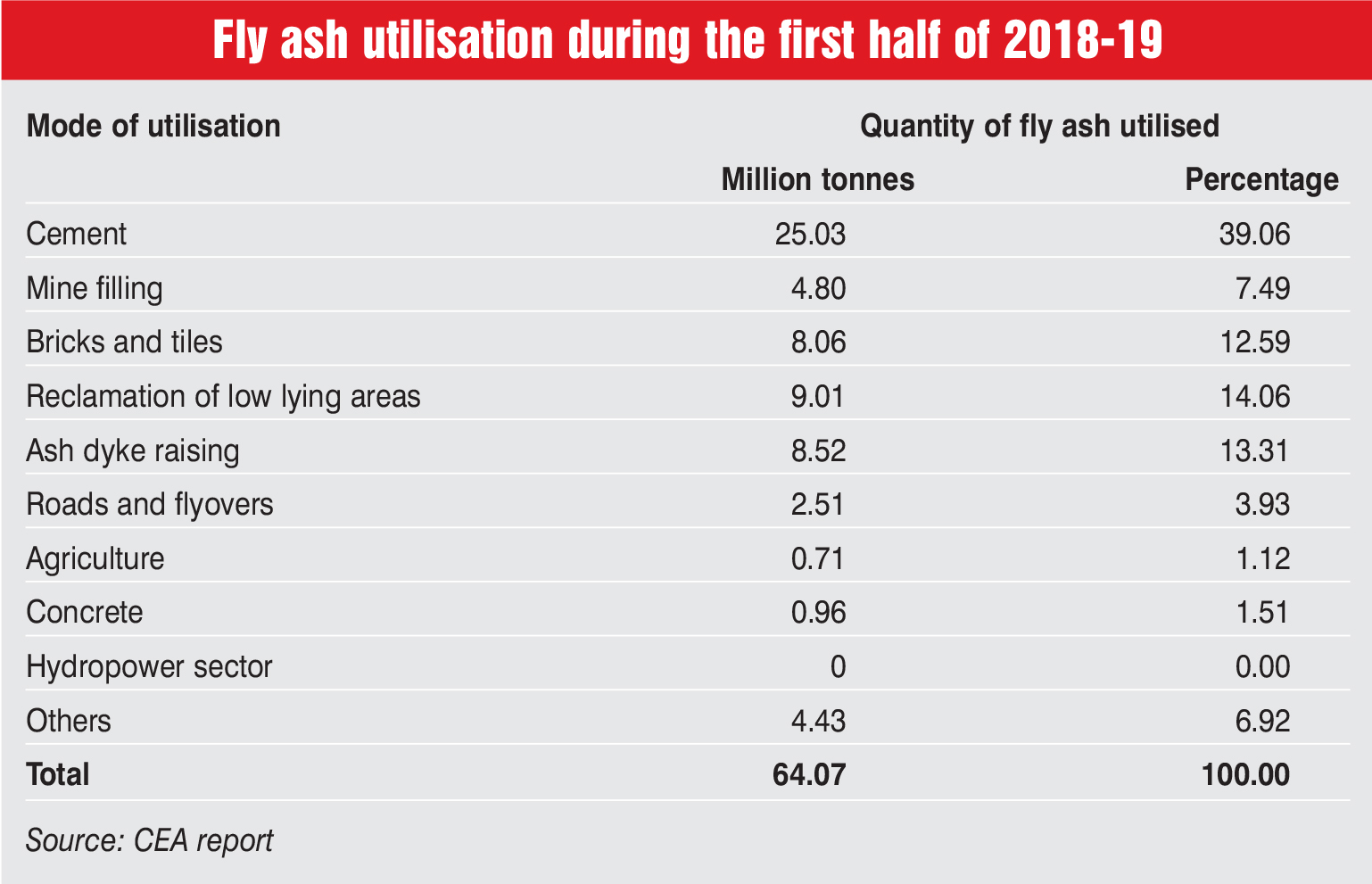

The cement industry is the biggest consumer of fly ash in India, with 39 per cent share in the total utilisation. Blending fly ash in cement is environmentally sustainable and financially attractive since it reduces the requirement of coal and limestone in cement manufacturing. Around 14 per cent of fly ash was utilised as a substitute for soil or sand to reclaim low-lying areas, thereby saving the fertile topsoil. Besides these, fly ash is used in the manufacturing of bricks and concrete, which binds ash and prevents it from escaping into the environment. Fly ash-based bricks and tiles are as good as clay-based conventional bricks. Another use of fly ash is in building roads and embankments since it is lightweight and compressible. In the agricultural sector, fly ash, being rich in micronutrients, helps in early maturity of crops, improves soil aeration, and conserves plant nutrients and water without affecting the groundwater quality.

The way forward

Fly ash utilisation improved from 55 per cent in 2013-14 to over 68 per cent in the first half of 2018-19. This can be largely attributed to several regulatory and policy initiatives taken by the government. These include setting fly ash utilisation targets, promoting its use in construction and agricultural activities, and mandating its use in government schemes. However, millions of tonnes of unutilised fly ash dumped at TPPs across the country is still a cause for great concern.

Given that coal-based generation will continue to account for a major share in the energy mix in the near to medium term and the environmental hazards posed by fly ash, there is need for a more proactive approach to fly ash utilisation.

The most practical form of fly ash utilisation is in infrastructure development on the plant premises. This could include buildings and roads, and ash dykes. This reduces the need to transport the ash, and thereby minimises the impact on the environment. Besides, TPPs can adopt technologies to produce ash in dry form so that it is readily usable by manufacturers of fly ash-based products. Besides, technologies to recover and treat wastewater from ash ponds are gaining traction.

In addition, there is a need to explore ways to increase fly ash use in other sectors including railways and agriculture. Stricter enforcement of the norms and targets by the government will be key to driving fly ash utilisation among TPPs.