Ensuring emission control in coal-based thermal power plants (TPPs) is crucial for facilitating a smooth energy transition in India. While renewable energy capacity is rapidly growing, coal-based plants are expected to provide grid stability in the near to medium term until energy storage technology is commercially scaled up. It is essential that these plants operate in an environmentally safe manner until they are phased out. However, the implementation of emission control equipment in TPPs has been slow, even seven years after the Ministry of Environment, Forest and Climate Change’s (MoEFCC’s) revised norms were notified in 2015. The deadline for meeting these norms has been extended multiple times, initially from 2017 to 2022, then to 2025, and now finally to 2027.

Emission norms

In December 2015, the Ministry of Environment, Forest and Climate Change (MoEFCC) issued revised emission norms for particulate matter (PM), sulphur dioxide (SO2), and oxides of nitrogen for TPPs. Initially, TPPs were required to install emission control systems by December 2017. However, the deadline has been extended several times.

Most recently, in September 2022, the MoEFCC extended the deadlines for TPPs to reduce sulphur emissions by an additional two years. Depending on their location, TPPs now have until December 2026 to comply with the emission norms. For coal-based units falling under Category A, the deadline for complying with the emission norms for SO2 has been extended from December 31, 2022, to December 31, 2024. Similarly, for TPP units under Category B, the deadline has been extended from December 31, 2023, to December 31, 2025. For all other TPPs falling under Category C across the country, the deadline has been extended from December 31, 2024, to December 31, 2026. Furthermore, according to the new rules, non-retiring TPPs that operate in a non-compliant manner beyond the specified timeline will be subject to environmental compensation. The compensation rates are set at Re 0.20 per unit for a duration of 0-180 days, Re 0.30 per unit for 181-365 days, and Re 0.40 per unit for 366 days and beyond.

With regards to NOx norms, power plants commissioned between 2003 and 2016 were previously required to cap their NOx emissions at 300 milligram per cubic metre (mg per Nm3). This has now been raised to 450 mg per Nm3. For plants commissioned from 2017 onwards, the limit for NOx emissions has been set at 100 mg per Nm3. For older plants commissioned prior to December 2003, the NOx limit has been set at 600 mg per Nm3. As per the MoEFCC’s notification in March 2021, the NOx standards are to be met by the specified timelines, by December 2022, December 2023 and December 2024 for Categories A, B and C respectively. Any deviation from these norms beyond the prescribed timelines will result in the levy of emission compensation.

The PM emission standards in the revised norms are also based on the installation dates of the plants. A limit of 100 mg per Nm3 has been set for plants commissioned till December 31, 2003, while for plants commissioned between January 1, 2004, and December 31, 2016, it is 50 mg per Nm3, followed by 30 mg per Nm3 for plants commissioned from January 1, 2017 onwards.

Progress on emission norms

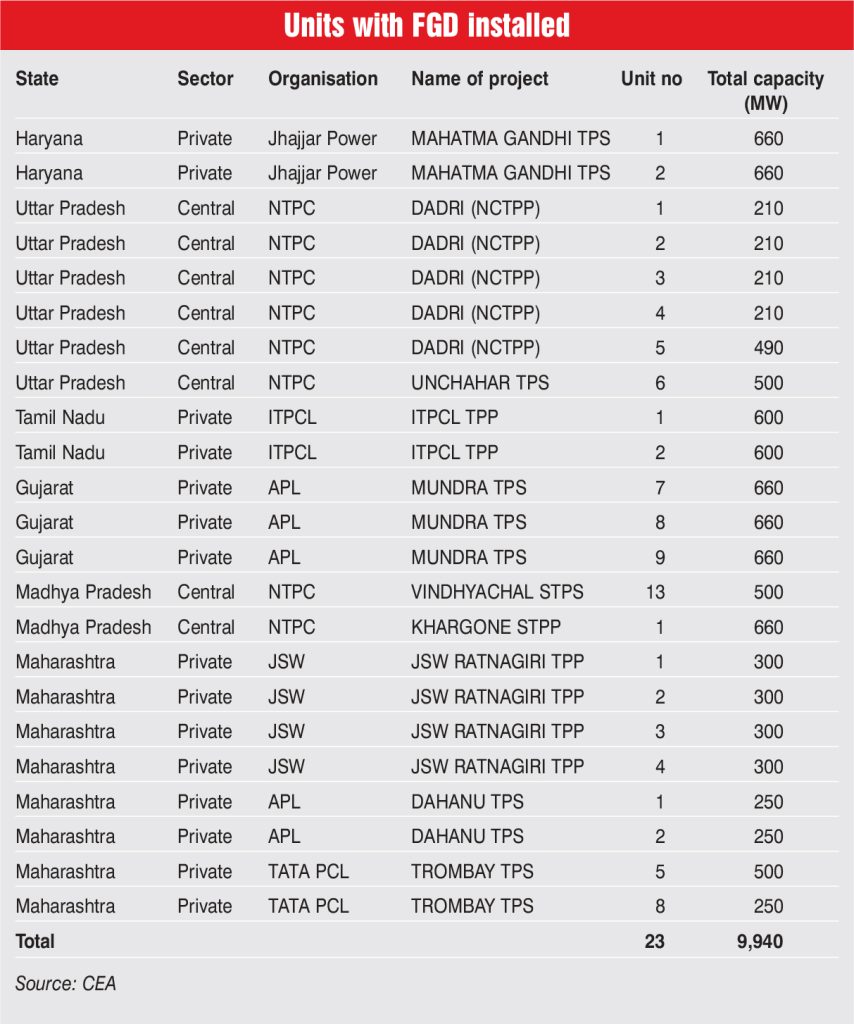

FGD Systems: According to the CEA’s data, as of July 2023, FGD systems for SOX control have been commissioned and are operational for 9,940 MW of capacity across 23 units. Of this, the central and private sectors have implemented FGD systems for about 30 per cent (2,990 MW) or eight units, and 70 per cent (6,950 MW) or 15 units, respectively. Bids have been awarded for 218 units aggregating 99,770 MW of capacity. Sector-wise, bids have been awarded for 90 per cent of the planned FGD capacity for centrally owned units, and only 22 per cent and 33 per cent of the state-owned and privately owned units respectively.

Update on NOx: To curb NOx emissions from thermal power plants, plant operators are increasingly installing emission control technologies such as selective catalytic reduction (SCR) and selective non-catalytic reduction (SNCR) to meet regulatory guidelines. NTPC Limited has awarded NOx combustion modification tenders for over 20 GW of capacity. Additionally, combustion modification work is at various stages of commissioning for 29 units with an aggregate capacity of 8.2 GW. Furthermore, combustion modification for 28 units aggregating to about 13 GW, including units located in the NCR (two units of the Dadri TPP and three units of the Jhajjar TPP), has already been completed. NTPC has also conducted pilot-based studies on SNCR and SCR technologies at seven stations with various SCR system suppliers, and has determined a technically viable emission limit after taking into consideration Indian coal. The results of the tests have been submitted to the Supreme Court.

Update on ESP: ESPs are the most commonly used PM emission control equipment in coal-based TPPs. They specialise in the removal of PM by electrically charging the ash particles in a flue gas stream. An ESP comprises a series of parallel vertical plates containing electrodes, which create an electric field through which the flue gas is passed in order to separate the particles. Given their high collection efficiency of over 99.99 per cent for a particle range of 0.01-100 micrometres, most power plants in the country have already installed ESPs. However, ESPs do not work well for fly ash with high electrical resistivity, limiting their collection efficiency. The country’s largest power generator, NTPC Limited, has awarded packages for the renovation and retrofitting of 52 ESP units in 10 stations. As of March 2022, work has been completed on 39 units at eight stations. Work is currently under way for around 4 GW of capacity across 13 units.

Issues and the way forward

Power producers face significant challenges when it comes to implementing the revised emission control norms. One of the primary obstacles is the uncertainty surrounding the complete recovery of additional capital and operational expenses associated with emission control equipment. Furthermore, power producers experience revenue loss during periods of downtime, and lenders are often hesitant to provide debt funding due to existing stressed portfolios, as well as environmental, social and governance considerations. Additionally, the lack of willingness on the part of promoters to inject equity further exacerbates the challenges. Moreover, the CO2 emissions per unit of power generated by coal-based TPPs are likely to increase with FGD implementation. The primary reason for this is that for every molecule of SO2 absorbed, a molecule of CO2 will be released into the atmosphere in all desulphurisation processes. Additionally, every 0.5 per cent of SO2 in Indian coal will produce an additional 0.5 per cent of CO2 burden. FGD installation leads to an increase of about 1 per cent in auxiliary power consumption. Therefore, coal consumption in TPPs is likely to increase by at least 1 per cent due to increases in auxiliary power consumption, depending on the FGD technology implemented in the TPP, leading to more greenhouse gas or CO2 emissions.

Conclusion

Based on the implementation of FGD systems so far, and various studies undertaken, there is a proposal to spread the timeline for Category C units over four years, namely 2028, 2029, 2033 and 2034. This distribution will be based on their proximity to million-plus cities, critically polluted areas and non-attainment cities, or the ambient air’s SO2 levels. This approach aims to facilitate a comprehensive assessment of the performance and effectiveness of emission control equipment. Additionally, it will provide an opportunity for timely corrective measures, if necessary.

Overall, compliance with emission norms by TPPs has been slow due to various challenges. However, moving forward, it is crucial for gencos and other stakeholders to take proactive measures in order to overcome these obstacles and meet the compliance deadlines. It is important to address the existing hurdles and prioritise adherence to the emission norms for the benefit of the environment and sustainable energy practices.