Achieving emission control in coal-based thermal power plants (TPPs) is crucial for facilitating a seamless energy transition. Despite the rapid growth of renewable energy capacity, coal-based plants are anticipated to uphold grid stability in the foreseeable future, catering to power needs until energy storage technology achieves commercial scalability. It is imperative for these plants to operate in an environmentally responsible manner until their eventual phase-out. However, the deployment of emission control equipment in TPPs has been sluggish. The deadlines for complying with standards related to emission control have been repeatedly extended, initially from 2017 to 2022, then to 2025, and now to 2027.

Key trends in coal-based power generation

Coal remains the primary power source in India, comprising 73 per cent of generation in 2020-21, due to abundant reserves. Despite renewable energy gaining traction, coal will continue dominating generation in the near future. Coal-based plants emit harmful pollutants like sulphur oxides (SOx), nitrogen oxides (NOx), and particulate matter (PM), contributing significantly to India’s pollution levels, as highlighted by an International Energy Agency study in 2015.

The national average thermal plant load factor (PLF) rose to 64.2 per cent in 2022-23 from 58.9 per cent in 2021-22 due to increased electricity demand and a slowdown in new thermal capacity addition. This is projected to surpass 65 per cent in 2023-24. However, long-term pressure on thermal PLF is anticipated due to the growing presence of renewable energy. While thermal generation will remain dominant in the coming decade, its share is expected to gradually decline from 75 per cent in 2022-23 to around 60 per cent by 2029-30, driven by the ascent of renewable energy.

Trends in TPP emission

According to the Central Electricity Authority (CEA), the monthly average SOx emissions in categories 1a (units commissioned on or before December 31, 2003, with capacities <500 MW) and 1b (units commissioned on or before December 31, 2003, with capacities ≥500 MW) was 943 mg per Nm3 and 994 mg per Nm3, respectively, as of September 2023. Meanwhile, for category 2a (units commissioned on or between January 1, 2004, and December 31, 2016, with capacities <500 MW) and 2b (units commissioned on or between January 1, 2004, and December 31, 2016, with capacities >500 MW), the monthly average SOx emissions stood at 771 mg per Nm3 and 943 mg per Nm3, respectively. In Category 3 (units commissioned on or after January 1, 2017) the monthly average SOx emission was 1,109 mg per Nm3. The monthly average NOx emissions in Categories 1 (units commissioned on or before December 31, 2003) and 2 (units commissioned on or after January 1, 2004, and on or before December 31, 2016) stood at 369 mg per Nm3 and 291 mg per Nm3, respectively, as of September 2023. Meanwhile, for Category 3, the monthly average NOx emissions was 316 mg per Nm3. The monthly average PM emissions in Categories 1 and 2 were 96 mg per Nm3 and 41 mg per Nm3, respectively, as of September 2023. Meanwhile, for Category 3, the monthly average PM emissions stood at 30 mg per Nm3.

According to Tata Consulting Engineers Limited, Indian coal with a sulphur content of 0.5 per cent is projected to emit 2,012 mg per Nm3 of sulphur dioxide (SO2). In contrast, imported coal with the same sulphur content will emit 1,326 mg per Nm3 of SO2. This indicates that the sulphur content in Indian coal is relatively higher than that of imported coal.

Emission norms

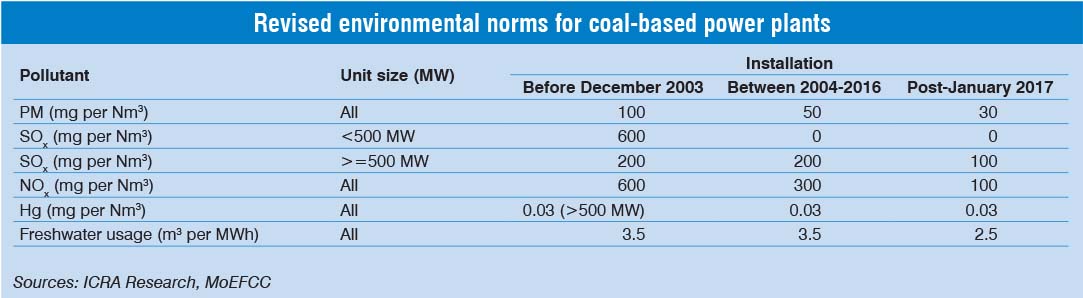

In December 2015, the Ministry of Environment, Forest and Climate Change (MoEFCC) updated the emission standards for PM, SO2 and oxides of nitrogen for TPPs. Originally, TPPs were required to install emission control systems by December 2017, but this deadline has been extended multiple times. In September 2022, the MoEFCC extended TPPs’ sulphur emission reduction deadlines by two years, now due by December 2026. For Category A coal-based units, the SO2 emission norms deadline shifted from December 31, 2022, to December 31, 2024. Likewise, for Category B units, it changed from December 31, 2023, to December 31, 2025. Category C TPPs’ deadline was extended from December 31, 2024, to December 31, 2026. Further, non-compliant TPPs will face environmental compensation charges, ranging from Re 0.20 to Re 0.40 per unit, depending on the duration of non-compliance.

Regarding NOx standards, power plants commissioned between 2003 and 2016 initially had a NOx emissions limit of 300 mg per Nm3, which is now raised to 450 mg per Nm3. For plants commissioned from 2017 onwards, the limit is set at 100 mg per Nm3. Older plants commissioned before December 2003 have a limit of 600 mg per Nm3. The MoEFCC’s March 2021 notification set the deadlines for compliance – December 2022, 2023, and 2024 for Categories A, B, and C, respectively. Failure to meet these standards will incur emission compensation charges. The revised PM emission standards vary based on plant installation dates. Plants commissioned until December 31, 2003, have a limit of 100 mg per Nm3, while those commissioned between January 1, 2004, and December 31, 2016, have a limit of 50 mg per Nm3. Plants commissioned from January 1, 2017, onwards must adhere to a stricter limit of 30 mg per Nm3.

Update on emission norm compliance

Flue gas desulphurisation (FGD) systems are planned for 600 units totalling 211.52 GW capacity. According to CEA data, as of October 2023, FGDs are operational for 24 units totalling 10,600 MW capacity. Bids have been awarded for 227 units, totalling 102,960 MW capacity. These include 133 units in the central sector, 48 in the state sector and 46 in the private sector. Moreover, a tender notice has been issued for 25,895 MW capacity across 89 units.

To reduce NOx emissions from TPPs and meet regulations, operators install technologies such as selective catalytic reduction and selective non-catalytic reduction. Electrostatic precipitators (ESPs) are commonly used in coal-based TPPs to control PM emissions by charging ash particles present in flue gas. Although highly efficient (over 99.99 per cent for particles of 0.01-100 micrometres), ESPs struggle with high-electrical-resistivity fly ash, limiting their effectiveness. The CEA notes that 419 units (149,591.5 MW) comply with combustion modification, and 423 units (169,736.5 MW) have undergone ESP upgrades.

Monitoring power plant parameters aids in the early detection of performance issues. Modern technology, such as data analytics, internet of things, machine learning (ML) and artificial intelligence pinpoint deviations, thereby reducing energy loss, boosting efficiency, preventing downtime, cutting unnecessary maintenance and enhancing overall performance. Efficient operations enable power plants to generate more electricity using less coal per unit, resulting in reduced emissions. Digital technologies such as sensors, data analytics and ML enable the real-time monitoring of crucial parameters in TPPs, such as pollutant levels and plant performance. Continuous monitoring enables TPPs to detect inefficiencies, optimise combustion and minimise emissions. Sensors installed throughout the plant can detect deviations and facilitate prompt automated adjustments for efficiency and emission reduction. Additionally, digital monitoring aids in regulatory compliance by providing accurate data for reporting.

Cost recovery mechanism

The Central Electricity Regulatory Commission, in its order dated August 13, 2021, established a mechanism for recovering costs incurred by TPPs to ensure compliance with revised emission norms. This mechanism applies to competitively bid projects under Section 63 and projects without pre-specified formulas for relief under the “change in law” clause in PPAs. Costs will be recovered through supplementary capacity and energy charges over the 25-year useful life of emission control equipment. This may negatively affect returns for developers with plants having a remaining useful life of less than 25 years. Additionally, developers can recover increased costs for auxiliary consumption and reagent expenses at the generating station.

Mitigating CO2 emission

Carbon capture and storage technology captures carbon dioxide (CO2) emissions from industrial processes like power generation and stores them underground, preventing their release into the atmosphere. CO2 is captured from combustion flue gases before emission, transported via pipelines and securely stored underground in geological formations.

Biomass co-firing is another strategy that TPPs are employing to reduce emissions while diversifying their fuel sources. Biomass like wood pellets, agricultural residue and energy crops can be burned alongside fossil fuels in existing boilers. While biomass combustion emits CO2, it is considered carbon-neutral because plants absorb CO2 during growth, balancing emissions. This approach significantly cuts net CO2 emissions compared to using fossil fuel alone. Biomass cofiring also encourages sustainable land management, reduces reliance on finite fossil fuels and bolsters rural economies.

Challenges and the way forward

Power producers face challenges in complying with updated emission control regulations, primarily due to uncertainties related to recovering added capital and operational costs for emission control equipment. Revenue loss during downtime, lenders’ hesitance to fund due to stressed portfolios and environmental, social and governance considerations further complicate matters. Challenges also arise from incomplete PPAs regarding the equipment’s lifespan, untied PPA capacities and potential merit order dispatch downgrades. Achieving emission standards compliance has been sluggish, highlighting the need for strict adherence to implementation timelines, especially the net-zero commitments. Additionally, given TPPs’ crucial role in grid stability, it is vital to ensure environmentally sustainable operation.