Being an agrarian country, India has abundant biomass sources. However, despite the huge opportunities these presents, biomass-based power generation has not achieved its potential. A significant number of biomass power projects have been closed over the past few years. In this article, the authors underline the need for a strategic and scientific approach to bring down losses and increase project efficiency for attaining viability…

Amid climate change concerns and fast depleting fossil fuel reserves, there has been a global emphasis on harnessing alternative sources of energy. Governments across the world are increasingly focusing on harnessing the potential of solar, wind, biomass, tidal, geothermal and hydropower resources as a step towards creating a sustainable and energy-secure world. The Indian government has also embarked on an ambitious renewable energy path, with a target of installing 175 GW of capacity by 2022. Currently, a lot of emphasis is being given to solar and wind energy development. However, one cannot ignore the contribution of biomass-based power production in renewable energy growth in the country. Biomass has been one of the main sources of energy in India, particularly in the rural areas.

Biomass and rural development

In the Indian context, biomass is a cost-effective solution for power generation in rural areas, where a large population still does not have access to reliable power. From the development point of view, biomass power generation has a positive impact on the rural economy. With a biomass availability of 120-150 million metric tonnes per annum according to the Ministry of New and Renewable Energy, including agricultural and forest residue, India has immense potential to bolster its rural economy.

Among all renewable energy sources, biomass is the only one that requires fuel for power generation. Nonetheless, the benefits of biomass-based power generation are unparalleled to other renewable energy technologies. Biomass-based power projects not only help in addressing the power woes in rural areas, but also lead to the creation of new job opportunities in village localities where such projects are set up. Several experts have emphasised that biomass-based power helps in empowering the rural population and therefore requires more encouragement for providing energy access in such areas and addressing the larger goal of sustainable development.

Challenges and complexities

Despite the immense potential for economic and sustainable growth, it has been observed that investments in biomass-based power projects have stalled in recent years in India. Several projects have been shut down for various reasons. This was not always the scenario. A decade ago, biomass-based power plants were booming because of the higher incentives provided under the clean development mechanism, favourable government policies, the low cost of biomass feedstock and the absence of competing industries. However, in the past few years, the segment has witnessed an exponential increase in biomass fuel prices while tariffs have not been revised in the same proportion, making a hole in the pockets of project owners.

Running biomass-based power plants now seems challenging, as there is a lot of dependence on agricultural yields for fuel. The entire fuel chain is very complex, which begins from the stage of crop harvesting. The process involves the collection of biomass feedstock after harvesting, stacking and baling. The fuel is then transported to the storage centres of power plants.

Issues relating to crop growing patterns, fuel properties and farmer awareness, as well as the challenges involved in the segregation, acquisition and transportation of fuel from agricultural fields to power plants do not help the cause of power plant owners. The unpredictable nature of biomass fuel with respect to cost imbalances, market competitiveness and storage complications has added to the distress of owners. The storage process also involves a number of measures to ensure that the fuel, when fed into the boiler, is in good condition, retaining its maximum calorific value.

The entire process requires complex planning and knowledge to capture the true value. Therefore, there is a need to look at ways to make biomass power projects sustainable and viable in the long term. Moreover, the emergence of competing industries has increased the demand for biomass fuel, resulting in a rise in the price of the fuel. Due to continuous price escalations and the constant export tariff, biomass-based power plants have been facing a financial crisis. This situation is more severe in biomass power plants that rely on feedstock that is available once or twice a year, depending on the crop cycle.

Therefore, there is a demand for strict policy and regulatory measures so that biomass projects remain viable over time and contribute towards inclusive growth of the country.

Restoring efficiency

There is a need to adopt measures to increase the viability of biomass projects. One such measure identified in the biomass fuel chain is the adoption of ways to minimise the degradation and loss of biomass fuel for efficient output. Storing biomass for meeting a power plant’s fuel needs throughout the year requires huge infrastructure and land. In recent times, a number of project owners have undertaken fuel assessment studies to estimate the unaccounted losses in the entire system, rectify the issues and increase the efficiency of these plants.

The purpose of such studies was also to establish the variables that govern the overall cycle efficiency, assess the impact of climate conditions on the fuel, and identify other hidden non-conventional factors that govern the entire economics. The complex issue of fuel loss assessment can be understood by breaking the entire process into simple investigatable steps. This has been illustrated in some of the fuel loss assessment studies carried out by Development Environergy Services Limited (DESL). The study matrix of fuel assessment of a biomass power plant is shown in Figure 1.

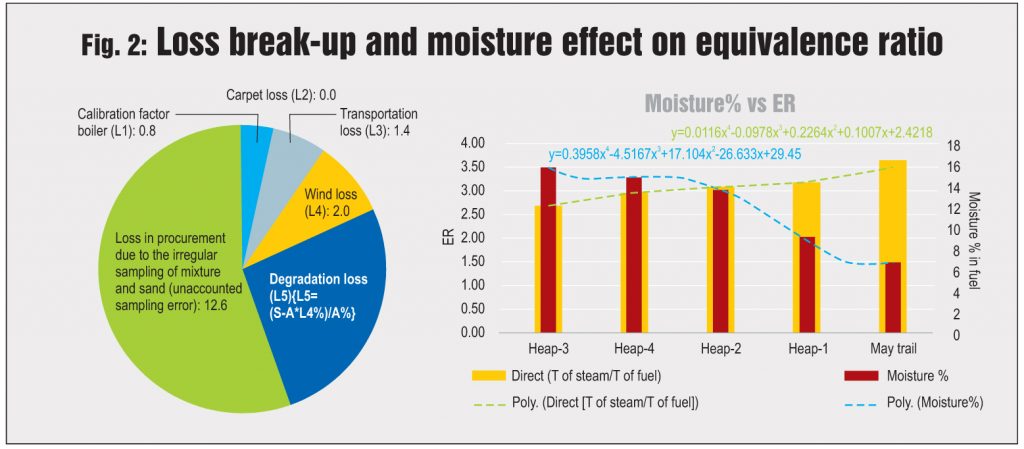

The fuel assessment study carried out at a biomass power plant in India by DESL for two years highlights several factors that lead to the degradation and loss of biomass fuel right from its transportation till final combustion in the boiler. The graphs in Figure 2 show the loss distribution, the impact of moisture and loss in boiler efficiency leading to a reduction in the final energy output.

Losses at the point of procurement of biomass fuel stood at about 12.6 per cent, followed by an average degradation loss of 6 per cent, average windage loss of 2 per cent and transportation loss of 1.4 per cent. Of all the losses, procurement loss is the highest and needs to be reduced.

The results were validated through reconciliation with the boiler performance. Intensive sampling and quality protocols were drafted to ensure the accuracy of the study. It was observed that rainfall, soil and wind play major roles in fuel loss. In addition, there was loss on account of calibration, rise in the moisture content due to rainfall, windage, etc. All these impact the overall efficiency of the boiler as well as fuel consumption. Losses due to fuel degradation are common in green fuels. Therefore, they need to be consumed at the earliest and not stored for long periods.

Conclusion

With the increase in biomass fuel prices every season and regulated electricity cost, it is necessary to adopt economical measures for operating power plants. In 2001, biomass prices were Rs 20-Rs 30 per quintal, which rose to Rs 200-Rs 230 per quintal in 2015. By 2020, prices are estimated to be in the range of Rs 300-Rs 400 per quintal.

Fuel management is a crucial step for preventing fuel loss. Windage loss is higher in a few areas with higher velocity and this cannot be totally eliminated, but can be reduced. However, increase in moisture due to rainfall can be controlled by covering the fuel with tarpaulin or plastic covers, which do not allow water to seep in. Other losses can be reduced by improving collection efficiency and monitoring at procurement points. Minimising fuel loss in the entire cycle chain is one way of improving the efficiency of biomass-based power plants, and thereby increasing profitability.

Dr G.C. Datta Roy,

Dr G.C. Datta Roy,

Adviser,

Development Environergy Services Limited