Switchgear is one of the most important components in an electrical system. It includes all the devices that ensure power system protection and regulate power supply. Switchgear de-energises equipment and clears faults in the system, thereby ensuring reliable power supply.

The switchgear industry in India mainly covers low voltage (LV) switchgear (with a rating below 1 kV) products. With huge emphasis on electrification, the medium voltage (MV) switchgear (with ratings between 1 kV and 33 kV) market is expanding at a rapid pace. The demand for high voltage (HV) and ultra HV (UHV) switchgear is also picking up on the back of investments being undertaken by the government for the development of HV and UHV transmission infrastructure. In addition, with the continuously increasing renewable energy capacity, switchgear has become pivotal in ensuring that networks operate in a synchronous manner with minimum faults. Further, modern business requirements call for upgraded switchgear that can ensure safety, reliable power supply and continued business operations. The switchgear industry has witnessed technological advancements across all voltage levels. Industry players are constantly trying to develop different kinds of switchgear that is more compact, reliable and environment friendly, and requires minimum installation and commissioning time. Power Line takes a look at the key switchgear technologies…

Air-insulated switchgear

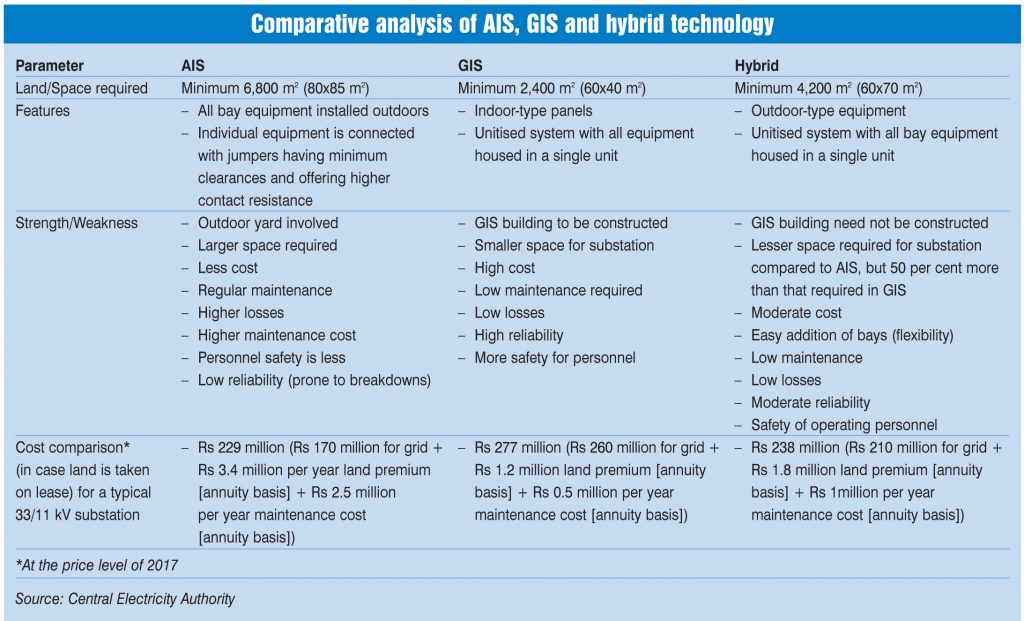

Air-insulated switchgear (AIS) is the most widely deployed switchgear in India and worldwide. It uses air as the primary dielectric for phase to phase and phase-to-ground insulation. AIS is popular where space is not an issue. It has low construction and maintenance costs. AIS is easy to maintain as all the equipment is within view and faults can be attended to without much delay. However, it is vulnerable to faults since the equipment is open to external elements such as human intrusion, pollution, deposition of saline particles, lightning strikes and extreme weather conditions.

Gas-insulated switchgear (GIS) is essentially compact and metal-encapsulated, consisting of HV equipment such as circuit breakers and disconnectors. In GIS, all the components including busbars, circuit breakers, the current transformer, potential transformers and other substation equipment is placed inside modules filled with sulphur hexafluoride or SF6 gas.

Traditionally, GIS uses or SF6 as the insulation medium. It maintains atomic and molecular properties even at high voltages, and has superior insulation properties. It also reduces the distance needed between active and non-active switchgear parts, thereby reducing the size of the equipment and making these ideal for urban areas as well as indoor spaces. The other advantages of GIS are its high safety index and low maintenance requirements. The high capital cost of GIS as compared to that of AIS is an issue, but if land as well as construction and maintenance costs are taken into account, it proves economical. Further, with the increase in voltage, the incremental investment required for GIS is less than that required for regular switchgear. Further, SF6 is a greenhouse gas with high global warming potential. With the environmental concerns associated with SF6, efforts are under way to replace it with an alternative medium.

ABB has achieved a recent breakthrough by commissioning the world’s first HV and MV pilot GIS bays with a new eco-efficient gas mixture in Zurich. This fluoroketone-based gas mixture has been developed especially for switchgear applications. The mixture contains carbon dioxide and oxygen for HV GIS, and nitrogen and oxygen for MV GIS. Similarly, Siemens has also introduced MV switchgear that does not require SF6 as the insulating gas. The system uses clean air consisting of only the natural constituents of ambient air, for example, nitrogen and oxygen, as the insulating gas. GE is also working on a technology, which is referred to as g3 or green gas, for the grid. It is compatible with the usual switchgear material. With g3, bay dimensions similar to those of the current SF6 bays can be realised at only a minor surcharge. Green gas has the lowest carbon footprint.

Hybrid switchgear

Hybrid switchgear combines conventional AIS and modern GIS technology, and can be installed both in indoor as well as outdoor areas. Some of the key advantages of hybrid switchgear are that it requires almost 30 per cent less switchyard area and lower foundations per bay. In a hybrid switchgear substation, circuit breakers, disconnector and earthing switches, voltage transformers and sensors, current transformers, and fast-earthing switches are enclosed in a single-phase gas-insulated housing while traditional air-insulated busbars are used to connect other equipment. As various functions in a hybrid switchgear substation are integrated, the distance between the components is reduced, thereby reducing the overall space requirement. They can be quickly installed (usually plug and play), are highly reliable and have a lower life cycle cost. GETCO is one of the pioneers in the installation of hybrid switchgear. A few examples are the 220 kV Sartanpur and 220 kV Suva substations. The utility is also implementing the Amod (upgradation of the 66 kV to 220 kV) hybrid substation, which is due for commissioning in March 2019.

Vacuum switchgear

A vacuum circuit breaker is mostly suitable for MV applications where the arc quenching takes place in a vacuum. It is now emerging as an alternative in HV applications as well due to the various advantages – compact size, higher reliability, lower maintenance and faster restoration. Vacuum switchgear has also seen a renewed interest with focus on reducing the use of SF6. It is expected that the deployment of vacuum switchgear at higher voltages will increase in the times to come. However, a few challenges pertaining to capacitor switching, continuous current performance, voltage sharing, etc. still need to be addressed before vacuum switchgear can be successfully deployed at higher voltages.

Solid-insulated switchgear

In solid-insulated switchgear (SIS), the main MV circuit is generally encapsulated in insulating materials (such as epoxy resin). Fundamentally, there is no difference in behaviour in an SIS and AIS. There is also no visible live part along the main circuit. However, the issue of electrical field variation exists in case of harsh environmental conditions. Shielded SIS (2SIS) is a more advanced technology with three concentric layers: a live part (main conductor, insert, or vacuum interrupter which is permanently connected to the network and is subject to voltage variations), an insulating layer (ensures insulation in all operating conditions) and a conductive layer (ensures electrical continuity and an effective earth connection). 2SIS technology offers various advantages such as no ageing of infrastructure, no three-phase or two-phase faults, and no internal arc effects.

Intelligent switchgear

Switchgear makers have started leveraging internet of things to enable real-time information flow, as well as improved predictive diagnostics that leads to higher energy efficiency and a more reliable grid. Intelligent switchgear can connect with the internet and provide comprehensive monitoring and protection functions, as well as measure all electrical parameters in real time. A smart switchgear has built-in protection and control intelligent electronic devices (IEDs). These new IEDs, combined with the latest information and communication technologies, form a base for enhanced protection, control and monitoring. Intelligent switchgear overcomes the disadvantages of common electric switchgear power systems by performing functions such as system diagnosis, electric fire prediction and prevention, and electric power demand prediction.

Conclusion

The switchgear industry’s growth has mainly been due to the strong demand for LV and MV switchgear from distribution and LV transmission consumers. With various transmission and distribution strengthening initiatives being undertaken by the government and the target to achieve 100 per cent household electrification, the switchgear market is likely to continue on its growth trajectory. It is a well-established and equipped industry with continuously developing technologies to support this growth. Further, given its critical role in substation automation, the scope of switchgear is set to grow considerably in the future.