Switchgear includes all the devices in power systems that provide protection and regulate power supply. Switchgear de-energises the equipment and clears faults in the system, thereby ensuring reliable power supply. Essentially, it protects the electrical circuit from overload, short circuit current and earth fault currents; isolates the faulty equipment from the rest of the circuit; and controls the circuits for functional switching, thereby ensuring the safety of the operator and uninterrupted supply. When a fault is detected, the switchgear immediately disconnects the faulty system to prevent damage and harm to the equipment or users.

In view of the growing renewable energy capacity, switchgear has become pivotal in ensuring that networks operate in a synchronous manner with minimum faults. Thus, it needs to be upgraded to ensure safety, reliable power supply and continued business operations. Power Line takes a look at the key switchgear technologies…

Air-insulated switchgear

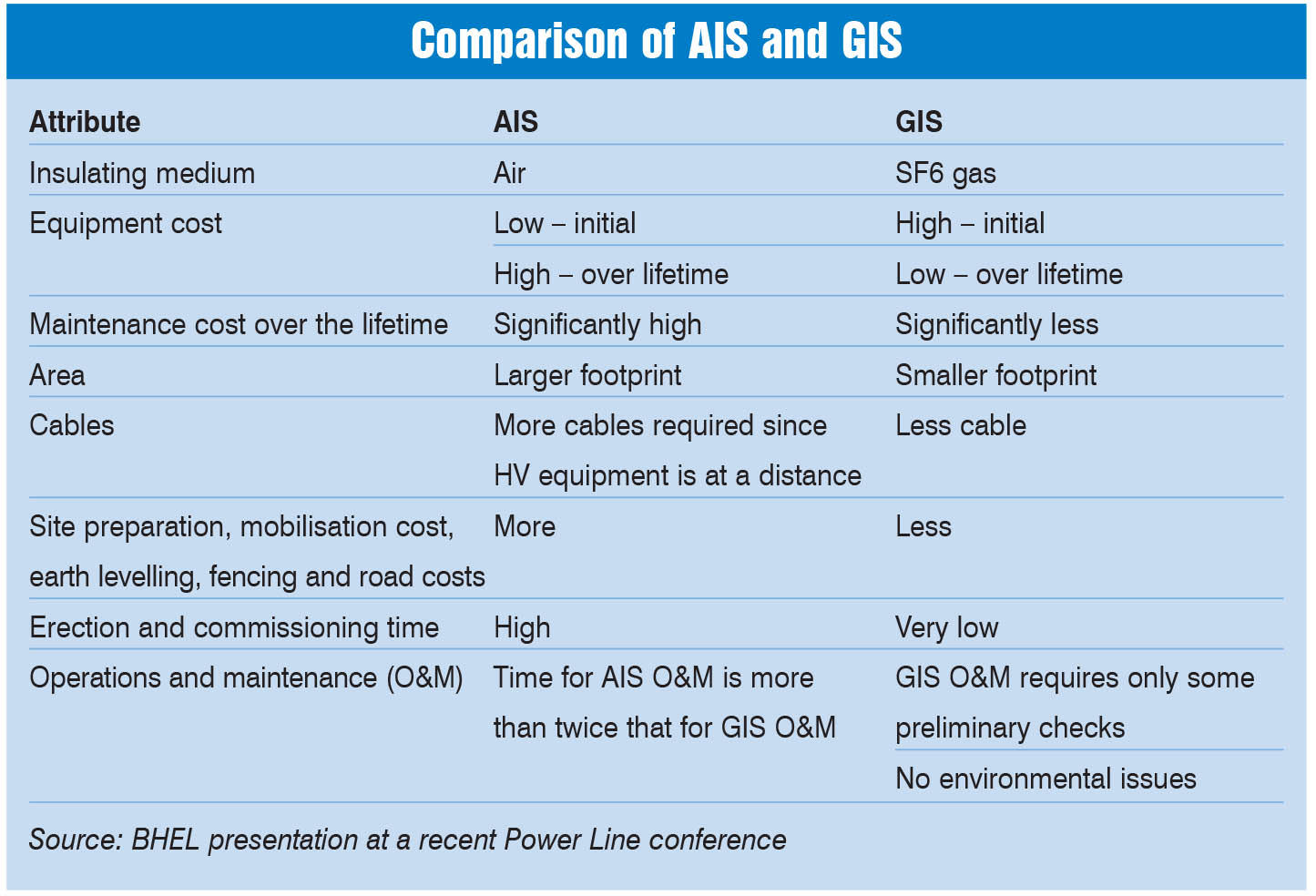

Air-insulated switchgear (AIS) is one of the largest switchgear types. It uses air as the primary dielectric for phase-to-phase and phase-to-ground insulation. It is installed at power plants that do not face any space constraints. As per the estimates of the Central Electricity Authority (CEA), AIS entails a low construction cost of Rs 229 million, but a high maintenance cost of Rs 2.5 million. It is easy to maintain as all the equipment is within view and faults can be attended to without much delay. However, it is vulnerable to faults since the equipment is exposed to external elements such as human intrusion, pollution, deposition of saline particles, lightning strikes and extreme weather conditions.

Gas-insulated switchgear

Gas-insulated switchgear (GIS) is metal enclosed switchgear, which is insulated using a gas (other than air) which is a little above the atmospheric pressure. It is essentially compact and metal encapsulated, consisting of high voltage (HV) equipment such as circuit breakers and disconnectors. In GIS, all the components including busbars, circuit breakers, transformers and other substation equipment is placed inside modules filled with sulphur hexafluoride or SF6 gas as the insulation medium.

The SF6 gas is a colourless, odourless, non-toxic, non-flammable gas with three times the insulating ability of air at the same pressure. It maintains atomic and molecular properties even at high voltages and has superior insulation properties. It also reduces the desired distance between active and non-active switchgear parts, thereby reducing the size of the equipment. This makes GIS ideal for urban areas as well as indoor spaces.

The other advantages of GIS are its high safety index and high reliability. As per CEA estimates, while GIS entails a high initial cost of Rs 277 million, its annual maintenance cost is about Rs 0.5 million. Taking into account both its high capex and low maintenance costs, GIS proves to be more economical. Further, with the increase in voltage, the incremental investment required for GIS is less than that required for regular switchgear. The failure rate of circuit breakers and disconnecting switches in GIS is one-fourth of that of AIS.

A drawback of GIS is the use of SF6 gas, which poses environmental concerns. AIS uses air as an insulating medium. However, efforts are under way to replace SF6 gas in GIS with an alternative medium. The latest GIS technology has a lower environmental impact with SF6 leakage rate reduced to less than 1 per cent.

Hybrid switchgear

In recent times, the switchgear industry has witnessed innovations such as hybrid switchgear. A hybrid switchgear is the combination of conventional AIS and high voltage GIS, and is primarily used in the renovation and extension of substations. The distinguishing feature of this type of switchgear is its compact and modular design, which allows for several functions in one module. It also provides a large variety of different layout configurations. Modularisation results in space, time and cost savings. Compact hybrid switchgear assemblies reduce space requirements by more than 50 per cent as compared to conventional open-type switchgear. Moreover, hybrid switchgear can be erected and installed faster. The use of standard components also decreases design faults.

Owing to the use of SF6 gas for encapsulation, hybrid switchgear does not require regular maintenance. The use of SF6 gas also increases the operational reliability of hybrid switchgear and makes it safe to use even in very demanding environmental conditions like polluted environments and extreme climates.

Other trends

Fixed mounted switchgear

Racking circuit breakers is a known cause of electrical arc flash events. In such events, fixed circuit breaker switchgear eliminates racking in and racking out. While racking is an uncommon issue, it mostly occurs due to improper breaker installation. They can increase in frequency due to lack of maintenance and ageing of equipment. As compared to withdrawable circuit breaker switchgear, it has a more compact design. While the former has a larger design, which requires rear access, it has a lower initial investment cost.

Shielded solid insulated switchgear

This is a new class of medium voltage (MV) switchgear, in which the entire MV live circuit path is grounded. The entire main circuit is insulated with epoxy, which eliminates the exposure of live parts. As a result, since there are no more exposed conductors, the chances of internal arc faults are extremely low. The epoxy coating also protects against dust, pollution, condensation, humidity, aggressive atmosphere, etc., reducing the maintenance requirements. Another benefit of MV switchgear is the reduction in phase-to-phase faults.

Intelligent switchgear

The increased use of supervisory control and data acquisition has increased the demand for intelligent switchgear. Switchgear manufacturers are now including built-in protection and control intelligent electronic devices in their switchgear solutions. These new IEDs combined with the latest information and communication technologies form a base for enhanced protection, control and monitoring. Intelligent switchgear will significantly enhance the efficiency and reliability of a grid and help utilities avoid blackouts and equipment failures. With the use of internal computer technology, this switchgear has overcome the shortcomings in electric switchgear. It can also perform functions such as system diagnosis, electric power fire predictions and electric power demand predictions.

Conclusion

Industry players are constantly developing different kinds of switchgear that are compact, cost effective and low maintenance. Wherever land is a constraint, GIS technology can be adopted. It also provides more safety and reliability. Hybrid technology may also be used by utilities to optimise space and cost, and may be most useful in the extension of existing substations. Further, the latest switchgear technologies must support renewable energy integration, smart grid infrastructure, and accommodate all generation and storage options. As more and more real-time data becomes available, switchgear must also be automated to support the digital economy.