Tighter control on emissions from sulphur oxide (SOx), nitrogen oxide (NOx) and particular matter (PM) has become a priority for many countries across the world. In India, the Ministry of Environment, Forest and Climate Change has issued stringent regulations that affect an estimated 140 GW of operating coal-fired power plants and all new plants to be built in the future. By 2022, SO2 emissions from all operating plants in India that are 500 MWe or larger in capacity must not exceed 200 mg per Nm3, and all new coal plants, regardless of capacity, and other special category plants must meet even tighter SO2 limits of 100 mg per Nm3. In other words, for an existing coal plant with baseline SO2 emissions in the range of 1,200-1,400 mg per Nm3, this amounts to an 80-90 per cent SO2 emissions reduction from uncontrolled levels.

Competing FGD technologies

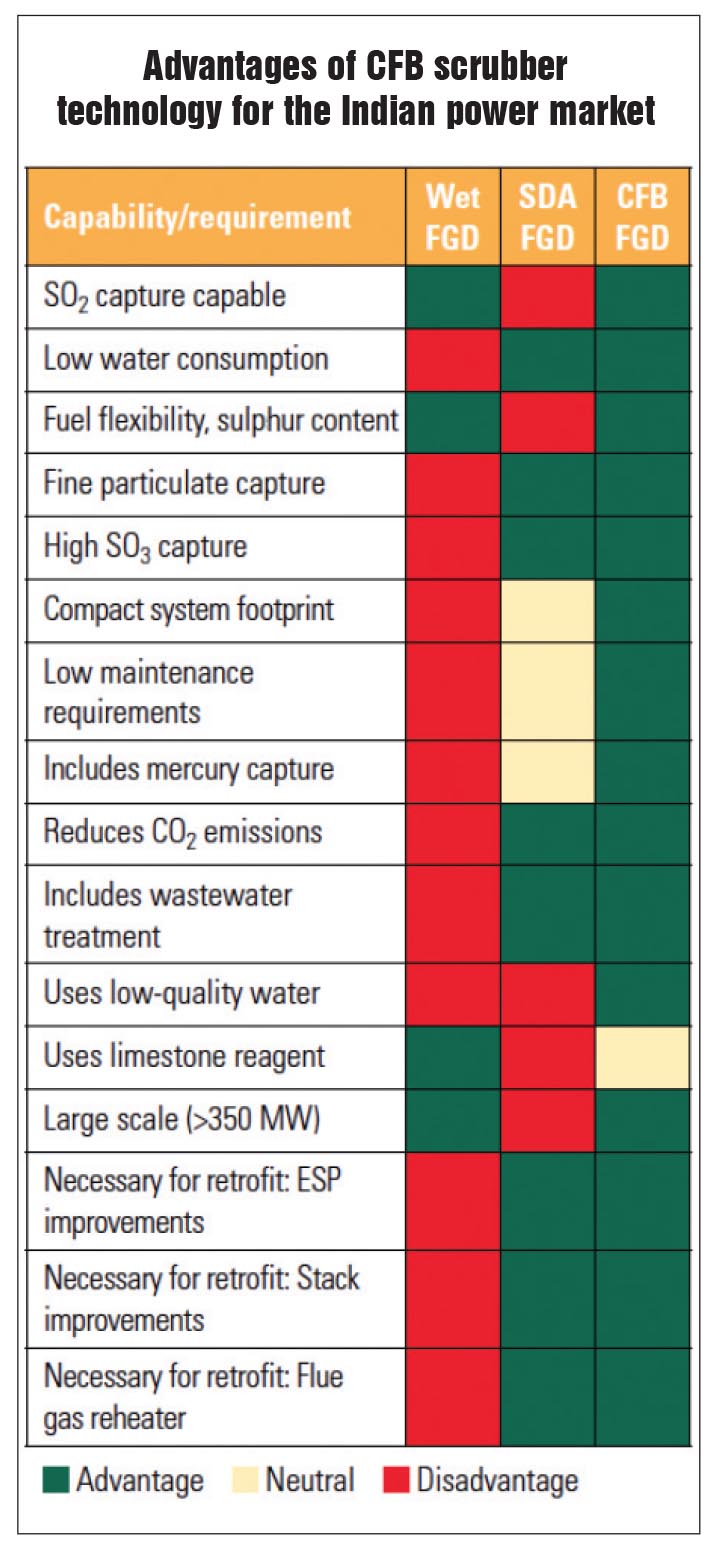

A flue gas desulphurisation (FGD) system can be selected from a wet, dry or semi-dry system depending on the level of SOx required to be removed and the plant specifics. The conventional approach to remove SO2 from coal-fired power plant flue gases has been through wet flue gas desulphurisation (wFGD) technology, or, to a lesser extent, through spray dryer absorber (SDA) technology. Another technology that might be better suited is circulating fluidised bed (CFB) technology, a dry FGD process that achieves increased SO2 removal with a much more fuel-flexible treatment process that is not dependent on wet chemistry.

Wet flue gas desulphurisation

Up until now, wFGD technology has been the incumbent FGD option preferred by power plants in India. This is primarily due to its proven track record in large-scale units, limestone cost, and its ability to produce gypsum as a by-product for possible sale. The wFGD process uses wet slurry produced from milled limestone mixed with water that is pumped through spray headers in the absorber vessel. Flue gas enters the bottom of the absorber vessel, below spray nozzles. The slurry droplets created by sprays flow in the opposite direction to the incoming flue gas in order to mix the SO2 with the calcium-rich reagent. The resulting wet chemical reaction produces a mixture of calcium sulphite and calcium sulphate (CaSO4), also known as gypsum. A portion of the slurry is continuously removed from the absorber, collected by a separate recovery process, and then dewatered with drum or belt filters. The gypsum recovered, if not commercially recycled, must be properly and permanently stored either on-site in containment facilities or transported to off-site locations.

wFGD technology is not economically viable due to drawbacks such as process equipment that requires a large footprint near the boiler island, very high water usage to make the slurry used for sulphur removal, and significantly increased auxiliary power consumption necessary to run wFGD systems. Some Indian thermal power plants that selected wFGD expecting to offset increased operation & maintenance expenses with gypsum sales have been disappointed. The quality of gypsum produced in Indian power plants has been poor due to low purity (less than 80 per cent) of local limestone. Also, the Indian gypsum market is saturated, so the expected income stream from the sale of gypsum has been replaced with recurring expenses on large-scale gypsum disposal.

wFGD plants require a long-term, reliable supply of high quality limestone. And, water usage is 30-40 per cent higher than either the SDA or dry CFB scrubber option. Finally, a plant with a wFGD system must significantly increase the operating, maintenance, and laboratory testing staff because the wFGD option is much more manpower intensive, particularly with respect to routine maintenance.

The wet desulphurisation process also requires expensive glass/plastic liners or stainless steel for the absorber vessel (which is not required by the other two SO2 removal processes). This significantly increases the capital cost, particularly for a single vessel system. The Indian power market is very price sensitive, so the much higher capital cost of a wFGD system vis-à-vis other technology options remains an important evaluation factor.

Spray dryer absorber

SDA sulphur removal systems are typically employed on plants that burn low to medium sulphur (less than 2 per cent) coal. SDA systems generally achieve sulphur removal efficiencies in the range of 90-95 per cent, depending on inlet conditions. Higher sulphur removal rates require the addition of a fabric filter that provides for the needed reaction and mass transfer time for the sorbent and SO2 to react in a surface filter cake.

The SDA process begins with a lime sorbent, usually quicklime (CaO), which is slaked with water to form a slurry reagent. Lime is typically stored in silos much like in the wFGD process. Slurry preparation can also use recycled dust from the plant’s particulate collection system for increasing the solid content of the slurry to improve SO2 removal efficiency. The reagent slurry is pumped to the top of the SDA absorber vessel and is led through one or more high speed spinning wheels within rotary atomisers located at the top of the absorber vessel to produce a spray cloud of reagent. The flue gas mixes with the spray cloud and the sorbent reacts with SO2 and SO3 to form calcium sulphite and calcium sulphate while simultaneously cooling the flue gas. The cooled flue gas leaves the absorber and enters the particulate collection system such as a fabric filter or an electrostatic precipitator.

Circulating fluidised bed scrubber

CFB scrubber technology is growing in popularity with plants up to 600 MW in capacity. The cost of installing a CFB scrubber system is around 60 per cent of a similarly sized wFGD system. In India, the average installed cost of a wFGD system is $65 per kW; this translates into immediate savings of almost $25 per kW in favour of a CFB scrubber system.

The operating essentials of a CFB scrubber system and its upflow absorber are very different from the SDA process. Flue gas with fly ash enters the bottom of the absorber, flowing upward through multiple venturis to accelerate the gas causing turbulent flow. There is no need for external lime preparation, so all the slurry mixing and handling equipment is eliminated. Instead, dry hydrated lime, Ca(OH)2, is directly injected into the CFB absorber along with the boiler flue gas and fly ash. An optional dry lime hydrator produces hydrated lime on-site from lower-cost quicklime.Recycled solids, reagents and water mix with the turbulent flue gas, which provides gas cooling, reactivation of recycled ash, and capture of pollutants. In short, unlike other technologies, the sulphur removal process in a CFB scrubber unit is independent of water usage.

The design of the absorber causes high turbulent mixing of the flue gas, solids and water to achieve high capture efficiency of the vapour phase acid gases and metals contained within the flue gas, unlike the wFGD or SDA processes. The gas and solids enter the fabric filter where solids are captured and recycled back to the absorber to capture more pollutants. Unique to CFB scrubber technology, reactive absorbents such as sodium carbonates, hydrated lime and activated carbon might be added to target specific pollutants like acid gases and organic compounds for capture first within the CFB absorber vessel and then again in the fabric filter as the flue gas passes through the filter cake.

There are other important cost advantages of CFB scrubber systems. Since the absorber has no high speed rotary atomisers (which require a high frequency of maintenance as they are prone to erosion, scale formation, and plugging) or lime slurry preparation equipment, annual maintenance of CFB scrubber systems is reduced by a factor of four compared to SDA and even more so compared to wFGD systems.

Globally, CFB scrubber systems have been employed at plants firing coal with a wide range of sulphur levels with no technical limit on the entering fuel sulphur content, unlike the alternative technologies discussed above. Fuel ash content seen in Indian fuels, up to 40-45 per cent, is perfectly acceptable for a CFB scrubber unit. Also, the flue gas temperature does not limit the amount of lime injection as it does when using an SDA system. This feature allows for a significant increase in acid gas scrubbing performance, should future air emissions regulations so require. This fuel flexibility is an important performance characteristic for those plants that receive coal from mines with poor coal quality and reduces or eliminates the need to burn imported coal. Sulphur dioxide removal efficiency has been demonstrated in excess of 95 per cent (case study see below) and up to 99 per cent depending on the entering SO2 loading. Also, unlike wFGD, CFB absorbers can be designed to remove 99 per cent of the SO3 because of the lime reagent’s high affinity for SO3. Other important design features and operating advantages of CFB scrubber technology that should be of interest to the Indian power market are shown in the accompanying fig.

Conclusion

For many thermal power plants in India, CFB scrubber technology is a compelling economic choice, particularly for units rated at 600 MW or less due to its lower installed cost, auxiliary power and water usage. CFB scrubbers also have a compact footprint and require low maintenance while ensuring high reliability. It’s a hard-learned truth that the number of regulated pollutants will increase in the future, particularly in developing countries, so multi-pollutant control capability should be included upfront rather than as an expensive afterthought. Moreover, the fuel-flexible CFB scrubber technology allows Indian power plants to purchase lower-cost opportunity fuels, including mixes of local fuels. The year 2022 is approaching and purchase decisions must be made very soon. Given these important characteristics, CFB scrubber technology enjoys distinct and quantifiable advantages over competitive FGD processes.

Robert Giglio, Senior Vice president, Sumitomo SHI FW