With thermal power plants contributing to the largest share in emissions, abatement of pollutants such as SOx, NOx and PM has become one of the top priority areas for power plant operators. Adding to the challenges is the fact that Indian coal is characterised by extremely high resistive dust and low sulphur content. The overall progress in compliance with emission norms, notified by the Ministry of Environment, Forest and Climate Change (MoEFCC) in December 2015, has been slow so far. In April 2021, the MoEFCC issued a new order on location-specific, category-wise compliance deadlines. This gives the majority of TPPs time up to December 2024 to meet the emission norms.

In the latest development, the MoEFCC released a notification in April 2021, extending the timelines for complying with the emission norms for coal-based thermal power plants (TPPs) by one to three years.

Revised timelines

In April 2021, the MoEFCC extended the deadline for complying with the emission norms for coal-based power plants by one to three years, based on the location of the plant. The Environment (Protection) Amendment Rules, 2021 classify coal-based units into three categories – Category A, which includes units within 10 km radius of the National Capital Region (NCR) or cities having population over 1 million, Category B, which includes units within 10 km radius of critically polluted areas or non-attainment cities, and Category C, which includes the remaining plants. A task force constituted by the Central Pollution Control Board (CPCB) has categorised 596 coal-based units into these categories. Accordingly, 79 coal-based units fall under Category A with a compliance deadline of December 2022, 68 fall under Category B with compliance deadline of December 2023 and 449 fall under Category C with compliance deadline of December 2024. While 11 per cent of the coal-based capacity falls under categories A and B, the majority of the capacity (around 78 per cent) falls under Category C.

In addition to the extension of timelines, the new rules will levy an environment penalty on non-retiring TPPs for non-compliance beyond the timeline. The maximum fine for defaulting plants under Category A is 20 paise per unit, whereas it is 15 paise per unit for plants in Category B and 10 paise per unit for plants in Category C. Apart from this, TPPs that are due for retirement before December 31, 2025 have been exempted from meeting the specified emission norms. However, these plants are required to submit an undertaking to the CPCB and the Central Electricity Authority (CEA) for exemption on the grounds of retirement. Furthermore, an environment compensation at the rate of 20 paise per unit electricity generated will be levied in such cases for operations beyond the date specified in the undertaking.

Update on emission norm compliance

Update on emission norm compliance

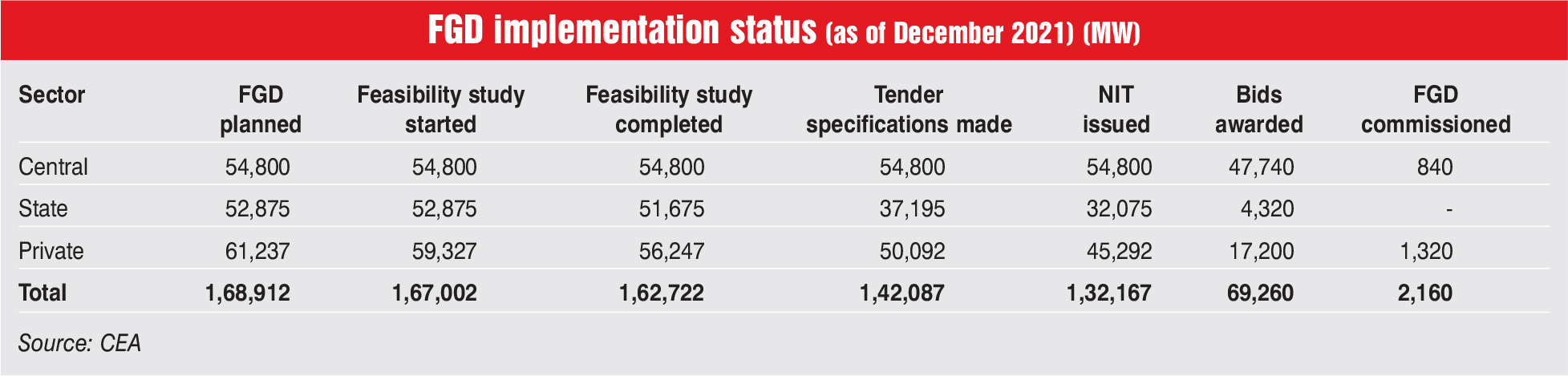

FGD implementation status: According to CEA data, as of December 2021, FGDs have been commissioned and are operational for six units of a total capacity of 2,160 MW – four units of NTPC’s Dadri project (4×210 MW) and two units at CLP India’s Haryana project (2×660 MW). Meanwhile, bids have been awarded for 157 units aggregating 69,260 MW in capacity, representing around 41 per cent of the total planned capacity. Sector-wise, bids have been awarded for 114 units in the central sector, 31 units in the private sector and 12 units in the state sector, representing 72.6 per cent, 19.8 per cent and 7.6 per cent of the total planned capacity. Apart from this, notice inviting tender (NIT) has been issued for 132,167 MW of capacity for 325 units.

Technology-wise, one of the most widely used technologies for SOx control is wet flue gas desulphurisation (FGD) based on limestone. Wet FGD systems roughly have SOx removal efficiency of over 90 per cent. Depending on the re-agent used, FGD can be classified as seawater based, ammonia based or limestone based. A majority of upcoming FGD systems are based on wet limestone technology. NTPC Limited is setting up wet FGD technology at most of its TPPs including the 1,320 MW Solapur Super TPP, the 1,320 MW Tanda Stage II project, the 500 MW Unchahar project and the 1,320 MW Meja power project. Another post-combustion SOx removal technology is dry sorbent injection. It is particularly preferable for small unit sizes in the 60-250 MW range. Notably, NTPC has opted for DSI at its Dadri power plant.

NOx emission control: NOX outflows can be brought down to 300-600 mg per Nm3 by utilising strategies such as combustion modification procedures. However, for additional reduction of 100-300 mg per Nm3 emission levels, advanced control procedures are required, which include selective catalytic reduction (SCR) and selective non-catalytic reduction (SNCR). To bring down the NOx emission to the extent possible, NTPC has awarded combustion modification for over 20 GW of capacity. It has completed combustion modification work at 16 units aggregating 7 GW in capacity including units located in NCR, that is, two units of the Dadri plant and three units of the Jhajjar plant. Further, it has awarded combustion modification works for 34 units aggregating 14 GW. Apart from combustion modification, SCR/ SNCR are proven technologies for low ash coal for Nox emission control, however, it is yet to be proven for abrasive and high ash content Indian coal. In view of this, NTPC is undertaking various pilot tests and studies to assess the suitability of SCR technology for Indian coal.

ESP upgradation/installation: The majority of TPPs already have installed commercially proven indigenous ESPs, to control PM emissions. However, upgraded ESP systems are required to comply with the tightened emission norms. A detailed proposal outlining the plan of action for the augmentation of ESPs for SPM control up to 2024 has been prepared by the CEA. An ESP upgradation plan has been prepared for over 65 GW of capacity.

The way forward

A recent CEA report on SOx norms compliance notes that there should be longer duration plan (up to 2035) for adopting the new emission norms for power plants falling under category C to help in understanding the performance of emission control equipment, their effectiveness and give a time for course correction. Apart from this, the CEA has suggested that a task force be constituted for smooth implementation of new environment norms considering phased manufacturing programme of FGD equipment under the Atmanirbhar Bharat Abhiyaan. The report also suggests study of sulphur dioxide reduction against carbon dioxide increase in flue gas emission by FGD systems, and accordingly exemption may be given to units where SO2 level in the ambient air is less compared to the permissible limit.

With regard to the challenges facing developers in emission norm compliance, a major issue pertains to the uncertainty regarding full recovery of additional capital and operational expenditure to be incurred on equipment. There is no clarity on the mechanism for recovery of FGD-related costs for projects that sell power through the short-term market. Another challenge in emission control compliance pertains to securing debt financing for projects that do not have long-term power purchase agreements (PPAs), for projects that have unviable tariffs as per their PPAs, or those that have a remaining PPA tenor of less than 12 years. The other issues in emission norm compliance include long time taken by regulators to process petitions, possible downgrade in merit order dispatch, import restrictions, and inadequate domestic technology.

Overall, the emission norm compliance by TPPs has been slow and the recent extension in the deadline has brought in significant relief for developers. Going forward, strict adherence to the implementation timeline is desired, especially in view of India’s climate change commitment at the COP26 summit. As India aims to “phase down coal”, the coal-based power generation segment would need to work towards measurable reduction in emissions in a timely manner.