The renovation and modernisation (R&M) of power plants is a promising solution to upgrade old units in order to increase generation, reduce emissions and enhance flexibility. A centrally sponsored scheme was launched in 1984 for R&M and life extension (LE), benefiting several thermal generating units over the years. In February 2020, the revised policy guidelines for R&M/LE of coal/lignite-based stations were released by the Central Electricity Authority (CEA) to align them with the changing requirements of the power sector.

R&M is now not limited to plant performance improvement. With the country’s goal to cut carbon emissions by 1 billion tonnes (bt) and lower emissions intensity of GDP by 45 per cent by 2030, the installation of emission control equipment at thermal power plants (TPPs) is crucial, which requires R&M. In addition, TPPs need to be made more flexible to incorporate the growing share of renewables, which is targeted to meet India’s 50 per cent energy needs by the end of this decade. This too would necessitate R&M of TPPs to increase their ramp rates and adjust to cyclic load variation.

Further, there is a need to prepare TPPs for biomass co-firing so as to lower their water consumption and thereby reduce their environmental footprint. The earlier guidelines were framed primarily for unit ratings of 100 MW or less and 200/210 MW units. However, in recent years, many units of higher ratings like 500 MW have outlived their lives and need R&M/ LE interventions. In view of this, the revised guidelines were released.

Current status

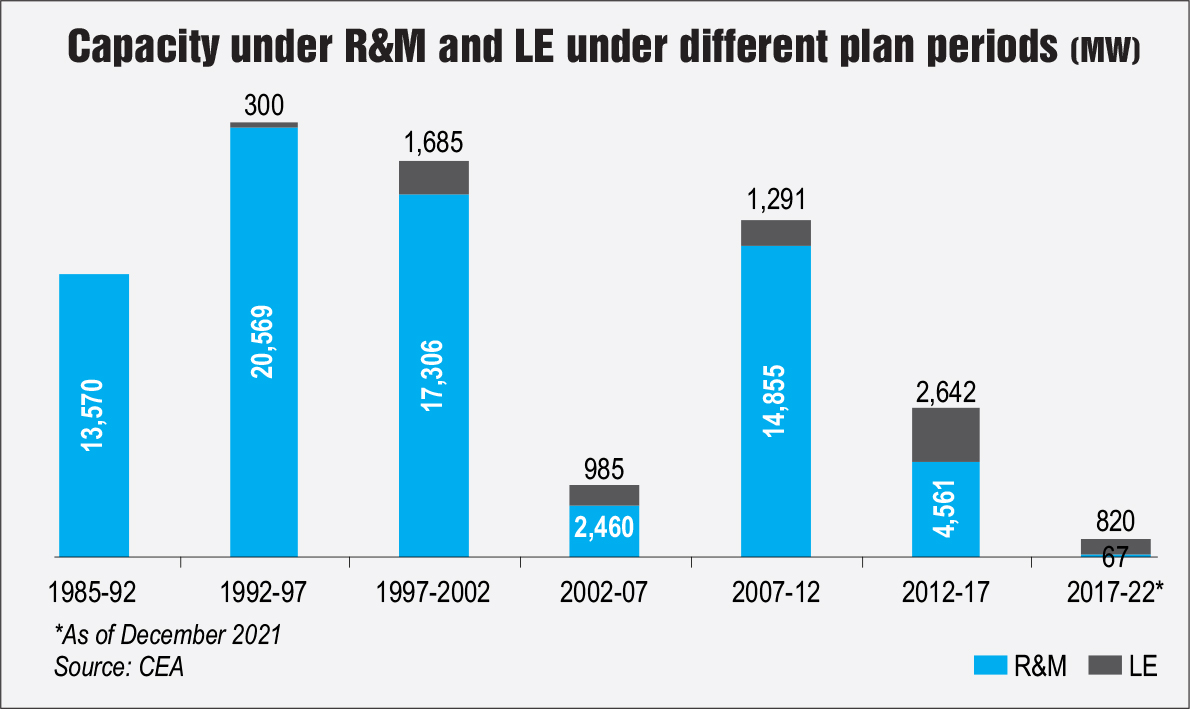

During 2017-22, R&M/LE works are planned for 14,929 MW of capacity across 71 units. However, as of December 2021, works have been completed only in six units aggregating 887 MW. The pace of implementation of R&M/LE has slowed down considerably in recent years. During 2007-12 (Eleventh Plan period), R&M/LE works were carried out for 17,000 MW of capacity, and in 2012-17 (Twelfth Plan period), works were carried out for about 7,200 MW of capacity. Overall, between 1985 and 2017, over 80 GW of capacity has benefited as a result of R&M/LE interventions.

The six units where R&M/LE works have been completed during 2017-22 (as of December 2021) include Units 3 and 6 (33.5 MW each) of North Eastern Electric Power Corporation Limited’s Kathalguri gas-based power plant; the 200 MW Unit 4 of the Ukai thermal power station (TPS) and 210 MW Unit 3 of the Wanakbori TPS owned by Gujarat State Electricity Corporation Limited (GSECL); the 210 MW Unit 6 of Maharashtra State Power Generation Company’s (Mahagenco) Koradi TPS; and the 200 MW Unit 12 of Uttar Pradesh Rajya Vidyut Utpadan Nigam Limited’s (UPRVUNL) Obra TPS. Further, three units are currently under shutdown for R&M/LE works – the 100 MW Unit 7 and 200 MW Unit 13 of UPRVUNL’s Obra TPS, and the 110 MW Unit 6 of Bihar State Power Generation Company Limited’s Barauni TPS.

Focus on emission control

Focus on emission control

As per the CEA, flue gas desulphurisation (FGD) systems have been planned for 439 units aggregating 168.9 GW to reduce SOX emissions. As of December 2021, bids have been awarded for 157 units aggregating 69,260 MW. This represents 41 per cent of the total planned capacity. Sector-wise, bids have been awarded for 114 units in the central sector, 31 units in the private sector and 12 units in the state sector, representing 87 per cent, 28 per cent and 8 per cent of the respective sector planned capacity. Apart from this, a notice inviting tender has been issued for 132,167 MW of capacity or 325 units.

Currently, FGD systems have been commissioned across 20 units aggregating 8,290 MW in capacity. These include CLP India’s Jhajjar TPP Units 1 and 2 (2×660 MW); NTPC Limited’s Dadri TPP Units 1-4 (4×210 MW) and Vindhyachal TPP Unit 13 (500 MW); IL&FS Tamil Nadu Power Company’s TPP Units 1 and 2 (2×600 MW); Adani Power’s Mundra TPP Units 7-9 (3×660 MW); JSW Energy’s Ratnagiri TPP (4×300 MW); Adani Electricity Mumbai Limited’s Dahanu TPP (2×250 MW); and Tata Power’s Trombay TPP Units 5 and 8 (500 MW and 250 MW).

The TPPs have been categorised as per the revised timelines for meeting the emission norms. Category A comprises TPPs within a 10 km radius of the NCR or cities that have a million-plus population, and are required to meet the emission norms by December 2022. Category B comprises TPPs within a 10 km radius of critically polluted areas or non-attainment cities, which would have to meet the norms by December 2023. Category C will comprise all other plants, which have been given an extension till December 2024. TPPs declared to retire before December 31, 2025 are not required to meet the specified norms if they submit an undertaking to the Central Pollution Control Board (CPCB) and the CEA for exemption on grounds of retirement. An environment penalty will be imposed on non-retiring TPPs for non-compliant operation beyond the specified timeline. A task force constituted by the CPCB has assigned 596 coal-based units to the three categories. Accordingly, 79 coal-based units (13.3 per cent) fall under Category A, 68 units (11.4 per cent) under Category B and 449 units (75.3 per cent) under Category C. As a result, nearly 75 per cent of the TPPs in India are not liable to meet the emission norms before 2024.

For the control of particulate matter (PM) emissions, most TPPs have already installed electrostatic precipitators (ESPs) since Indian coal has high ash content. However, upgraded systems would be required for the existing projects. In addition, the environment ministry’s decision to do away with coal washing makes it more important for TPPs to invest in efficient PM control technologies. A detailed phasing proposal has been prepared by the CEA, outlining the plan of action for the augmentation of ESPs for PM control up to 2024. As of June 2021, ESP implementation plans were available for 222 units aggregating 64.5 GW.

For the control of particulate matter (PM) emissions, most TPPs have already installed electrostatic precipitators (ESPs) since Indian coal has high ash content. However, upgraded systems would be required for the existing projects. In addition, the environment ministry’s decision to do away with coal washing makes it more important for TPPs to invest in efficient PM control technologies. A detailed phasing proposal has been prepared by the CEA, outlining the plan of action for the augmentation of ESPs for PM control up to 2024. As of June 2021, ESP implementation plans were available for 222 units aggregating 64.5 GW.

Update on flexibilisation

The CEA has constituted a committee to oversee the implementation of measures for flexible operation of TPPs on the basis of pilot tests. So far, Bharat Heavy Electricals Limited (BHEL) has undertaken pilot tests at NTPC’s Mauda TPS and West Bengal Power Development Corporation Limited’s Sagardighi TPS. BHEL has also carried out flexibilisation pilots at GSECL’s Ukai Unit 6 where a minimum load of 40 per cent at a ramp rate of 3 per cent was achieved successfully. Likewise, up to 40 per cent loading tests were carried out at Maithon Power Unit 2 as of July 2021.

With the expected increase in renewable energy capacity, the aim is to have 60 per cent of the installed TPPs operating at 55 per cent minimum technical load. The Ministry of Power has set the timelines for achieving the flexibility target (55 per cent minimum technical load) in coal/ lignite-based plants by 2024. Accordingly, 20 per cent of the total TPP fleet must comply with the flexibility target by 2020, 30 per cent by 2021, 40 per cent by 2022, 50 per cent by 2023 and 60 per cent by 2024. As of end 2021, about 43 per cent of thermal capacity or nearly 90 GW was compliant with the 55 per cent minimum technical load norm.

The way forward

Typically, mid-life R&M is carried out after 100,000 hours of operation of a thermal unit. However, given the effects of cycling of thermal generating units in terms of increase in stress, creep-related failures, etc., residual life assessment and R&M are required at a much earlier stage. Going forward, utilities are expected to adopt a holistic approach to R&M/LE in order to meet the environmental norms as well as the flexibilisation targets.