Automation in transmission and distribution (T&D) provides utilities flexible control of systems, which can be used effectively to enhance efficiency, reliability and the quality of power supply. It is estimated that the automation market will grow faster than the overall T&D market. With the increasing requirement for reliable T&D infrastructure, there is an even greater need for automation solutions to cope with the new challenges that the grid is facing. Further, as the power sector moves towards its objective of creating a smart grid, a transformation of the grid infrastructure is needed, particularly in T&D substations.

Since substations are an integral part of T&D utilities’ electrical networks, grid substation automation systems (GSASs) are increasingly gaining prominence. A GSAS essentially equips a substation with intelligent electronic devices (IEDs), and control and automation capabilities in order to allow remote users to control its functioning.

Need for automation

The main objective behind implementing substation automation is to make the power system more reliable, secure and efficient. Automation solutions can help power utilities deal with the growing complexity of the grid.

The GSAS significantly reduces the manpower required for managing a substation. Existing substations can be easily automated using specific equipment. The deployment of GSAS involves the replacement of old equipment and control devices with supervisory control and data acquisition (SCADA)-compatible equipment. This enables centralised control and monitoring of substations, which reduces installation and maintenance costs, diminishes the chances of manual errors as well as improves equipment reliability.

Also, GSAS enables utilities to expand their network in remote locations. It is estimated that a typical distribution utility with a customer base of 1 million and aggregate technical and commercial losses of over 30 per cent can achieve savings of up to Rs 430 million per annum through substation automation. These savings are accrued through the redeployment of manpower in strategic functions, controlled load shedding, reduction in electricity overdrawal from the grid, and reduction of time required in fault detection and correction.

Today, the Indian power grid is facing a number of challenges and automation solutions can help overcome most of these. One of the major challenges is the growing electricity demand, which is putting pressure on grid infrastructure including substations. Automation solutions can help in better monitoring the grid and avoid events such as blackouts.

As electricity demand increases further, utilities need to explore options to supply enough power to meet peak loads. As creation and provision of spinning reserves for peak load hours requires high capex, utilities must adopt methods to reduce peak load in order to cut costs as well as to manage supply and demand. In such a scenario, substation automation can provide plausible technology for peak load shaving and demand response.

Also, given the accelerated addition of renewable energy in the power system, the need for integrating generation from these sources into the grid creates instability due to the infirm nature of these sources. In such cases, automation solutions can help overcome grid instability issues. Technology has evolved over the years and today advanced technologies are available to monitor and operate the grid more efficiently. Automation solutions can provide better visibility to the grid.

The GSAS has advanced disturbance and event recording capabilities in T&D networks, aiding in detailed and faster fault analysis. Besides, certain automation solutions can allow the power system to heal itself in emergency situations.

Further, automation solutions for forecasting are useful for identifying a potential grid security threat. Of late, concerns about cybersecurity amongst utilities have increased, thereby giving prominence to these solutions.

Lastly, substation automation mitigates the need for comprehensive wiring between the devices found in conventional substations as it provides network segmentation and IED reconfiguration. Point-to-point wiring networks entail high capex, are difficult to maintain, and increase the difficulty of fault isolation detection.

Requirements for substation automation

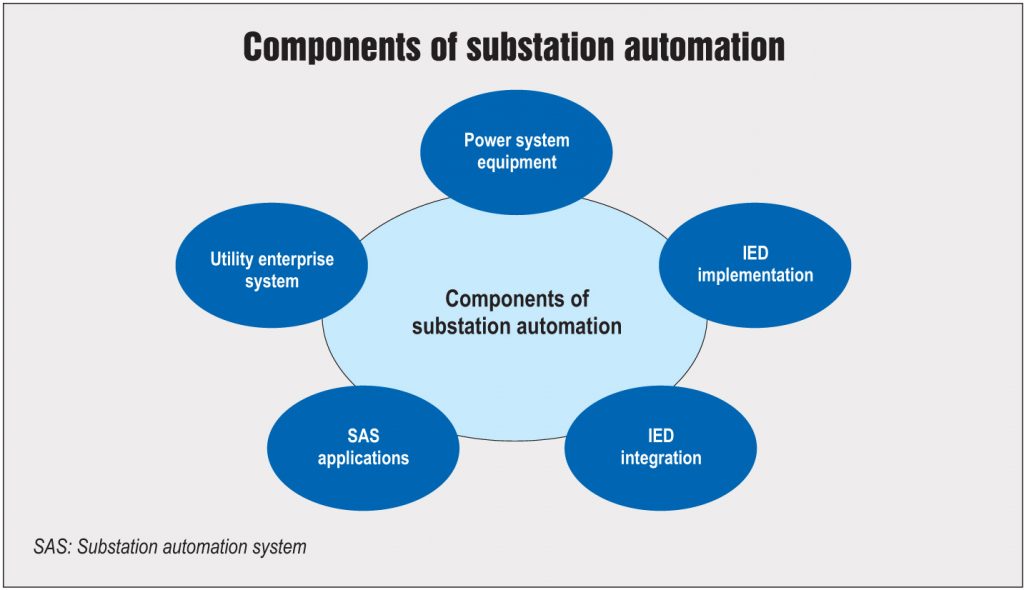

IEDs form the base for advanced remote functions such as advanced power system management and condition monitoring in substations. Automation further requires the installation of applications such as SCADA and alarm processing systems for integrated volt/var control. Substation automation can be broken down into five components: power system equipment (transformers and circuit breakers, etc.), IED implementation, IED integration, substation automation applications and utility enterprise.

The key factors that must be considered for selecting an automation system for substations are adaptability, distributed architecture and flexibility. The system should be adaptable to any vendor’s hardware. It should have a distributed architecture to minimise wiring. Further, it should be flexible and easy to set up by the utility.

The design of greenfield automated substations has the advantage of utilising the latest technology without many constraints. The new substation can deploy several IEDs for various functions as the major portion of operational data for the SCADA system will come from these IEDs. The IEDs can also be integrated with digital two-way communication systems. Typically, conventional remote terminal units (RTUs) are not present in the new substations and their functionality is addressed through IEDs, powerline carriers (PLCs) and integration networks.

Meanwhile, in the existing substations, different approaches for automation can be utilised depending on whether RTUs are installed or not. The utility can integrate the RTU with IEDs, or integrate the RTU as another IED, or retire the RTU and use IEDs and PLCs.

In either case (greenfield or existing substations), the automation system must interface with each of the IEDs in the substation and data from all the IEDs must be sent to the utility. Also, the system should be updated only when changes exceed their significant deadband.

It is important to note that the data type and substation control mechanism are dependent on the selection of IEDs in the system, which should be addressed on a case-to-case basis.

Further, the entire data required for operational purposes should be communicated to the SCADA system via a communication link from the data concentrator. Meanwhile, the data for non-operational purposes needs to be communicated to a dedicated data warehouse. The utility must establish a uniform communication protocol that allows communication between two devices. Any differences in the protocol of different devices may lead to communication errors. The substation integration and automation architecture must allow devices of different makes to interoperate using a standard protocol.

Also, the substation host processor must align with the relevant standards and specifications, possess strong networking abilities and support an open architecture. Besides, the local area network of the substation should adhere to the interoperability standards. Care must be taken to ensure that the substation’s user interface is designed intuitively to ensure optimal use. There is also a need to develop an interface with the energy management system (EMS) that allows utilities to monitor and control each substation and the EMS.

Conclusion

Globally, increasing competition is driving utilities to focus on upgrading ageing substations to enhance productivity, reduce costs and increase customer satisfaction. Older substations can be easily upgraded using modular automation systems. In India, however, there are some challenges to automation. First, this market is very price sensitive given the dominance of state-owned utilities. Second, the market is quite dynamic as every year a new innovation is launched and so new automation solutions are required. Equipment suppliers need to understand the value chain from end to end and provide systems that cater to the entire network.

There is a need for policies that encourage the deployment of advanced automation technologies and solutions for power systems. Given the launch of the National Smart Grid Mission and the central government’s focus on the power sector, the deployment of intelligent automation solutions is expected to witness high growth.

Overall, the technological developments under way in the sector are encouraging. But a shift to new technologies involves high costs, which discourage the financially stressed state utilities. Therefore, a greater focus on research and development is required to bring down costs and encourage widespread deployment of automation technologies.