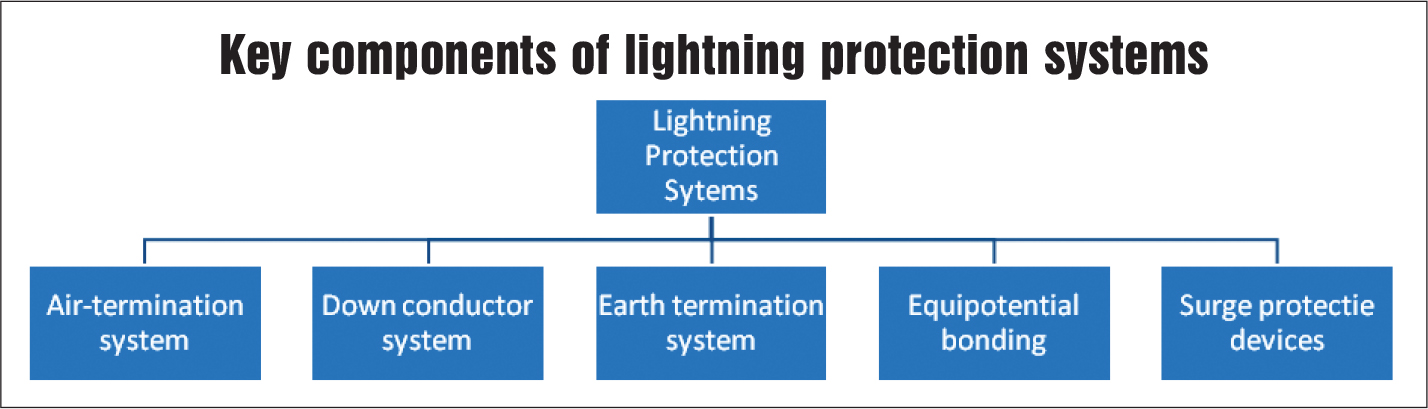

Earthing and lightning protection systems (LPSs) are used to protect buildings/structures from direct lightning strikes and possible heating effects as well as fires caused due to lightning currents. Typically, an LPS consists of an external and an internal protection system. An external LPS intercepts direct lightning strikes through an air-termination system, safely conducts the lightning current to the ground through a down conductor system and distributes the lightning current in the ground via an earth termination system. The internal LPS prevents sparking inside the building by establishing equipotential bonding or a separation distance between the components of the LPS and other conductive elements inside the building.

External LPS

Air-termination systems, down conductors and earth termination systems are the main components of external LPSs deployed in buildings. Air-termination systems typically consist of rods, spanned wires and cables, and conductors to avoid uncontrolled lightning strikes to a building. The correct design, position and dimensioning of air-termination systems are crucial for its proper functioning. Different methods can be used for the design and installation of air-termination systems such as the mesh method for flat roof type structures, the protection angle method for single masts and finials, and the rolling sphere method for all types of structures.

The most commonly used method for installing air-termination systems is the rolling sphere method, which is deployed universally and is especially useful for geometrically complicated rooftops/ buildings. 3D modelling is used to determine the zones of protection over the structure as it gives clear visualisation of the air-termination system and how lightning protection measures are integrated into the building’s architecture. In addition, drones are being used for the assessment of rooftop structures, especially in inaccessible areas, accurate analysis of LPS installations, and site evaluation for design purposes.

Further, air-termination systems for wind turbines are fast gaining significance as the risk of lightning strikes increases considerably for tower heights over 100 metres. At such heights, fires caused by lightning strikes are difficult to control using conventional fire-fighting equipment. Since lightning typically strikes the rotor blades of wind turbines, receptors are integrated in the rotor blades to provide defined points of strike (see Figure 1). In order to discharge the injected lightning currents to earth in a controlled way, the receptors in the rotor blades are connected to the hub via a metal connecting cable. Further, to protect structures such as anemometers on the nacelle from a lightning strike, air-termination rods or air-termination cages are installed.

After installing air-termination systems in structures, down conductors are laid to provide a passage for the intercepted lightning current to the earth-termination system to prevent damage to the building by the heating effects of the current. Certain key points that must be taken into consideration while designing/laying down conductors are: the conductors must offer several parallel current paths and the length of current path must be kept as short as possible without any loops/bends. The number of down conductors depends on the perimeter of the external edges of the rooftop and care must be taken to ensure that the conductors are distributed uniformly. Generally, high voltage-resistant insulated down conductors are used to ensure that the required separation distances from other conductive parts of the building structure, electrical lines and pipelines are maintained.

After installing air-termination systems in structures, down conductors are laid to provide a passage for the intercepted lightning current to the earth-termination system to prevent damage to the building by the heating effects of the current. Certain key points that must be taken into consideration while designing/laying down conductors are: the conductors must offer several parallel current paths and the length of current path must be kept as short as possible without any loops/bends. The number of down conductors depends on the perimeter of the external edges of the rooftop and care must be taken to ensure that the conductors are distributed uniformly. Generally, high voltage-resistant insulated down conductors are used to ensure that the required separation distances from other conductive parts of the building structure, electrical lines and pipelines are maintained.

The final component of an external LPS is the earth-termination system, which is the continuation of the air-termination system and the down conductors to discharge the lightning current to the earth. As part of the earthing arrangement, all the exposed conductive parts must be connected and the system must be capable of discharging the lightning current, avoiding a voltage rise in the earthing system itself and the surrounding ground. The earth electrode must have a low frequency resistance value and all the earthing components must offer both a low resistance to earth and have excellent corrosion resistance, as they will be buried in the ground for many years.

Fig. 1: Wind turbine with integrated receptors in the rotor blades

Internal LPS

For internal lightning protection for structures/buildings, equipotential bonding needs to be carried out in accordance with international standards (IEC 60364-4-41). Equipotential bonding reduces the potential differences caused by lightning currents by connecting all isolated conductive parts of an installation directly through conductors or surge protective devices (see Figure 2). Equipotential bonding involves joining together all metalwork and conductive items that are connected to the earthing system so that they all have the same potential energy (voltage). It helps reduce the risk of equipment damage and ensure the safety of occupants in case of a lightning strike.

Protective bonding conductors and bars are key elements of the equipotential bonding system. Equipotential bonding conductors do not carry operating currents and can, therefore, be either bare or insulated, and the bars must clamp all connecting cables and cross-sections so that they have high contact stability, carry currents safely and have sufficient corrosion resistance.

Surge protective devices are also used as a part of the internal LPS. These devices obstruct the flow of lightning currents through the equipment by giving it a special route to the earth, thereby preventing over-voltages and induction effects. In the case of electrical systems, surge protective devices are generally installed in parallel between the live conductors and the earth. The operating principle of surge protective devices is the same as that of a circuit breaker.

Fig. 2: Equipotential bonding

In normal use (when there is no over-voltage), the surge protective device functions like an open circuit breaker while in the case of over-voltages, the surge protective device becomes active and discharges the lightning current to the earth. The protective effect of a surge protective device works as long as the source of interference is reduced to a value below the interference or destruction limit and above the maximum continuous operating voltage of equipment to be protected. In addition, over-current protective devices, residual current protective devices and insulation monitoring devices are used for protection against electric shock under fault conditions.

Conclusion

Given the criticality of LPSs in maintaining the safety of buildings/structures, proper maintenance practices must be followed for fault-free operation. Like all electrical and electronic devices, the electronic components of LPSs, such as surge protective devices, cables and conductors, are subject to ageing. The maintenance and repair strategy should, therefore, focus on timely identification of surge protective devices that could fail in the near future. While corrective maintenance is carried out when devices fail due to overload and entails repair and/or replacement, preventive maintenance entails regular tests to ascertain the health of devices and take proactive measures before they fail. Further, condition-based monitoring is used in industries where maximum availability of systems and installations is required at all times and cost-effectiveness of maintenance measures is critical.