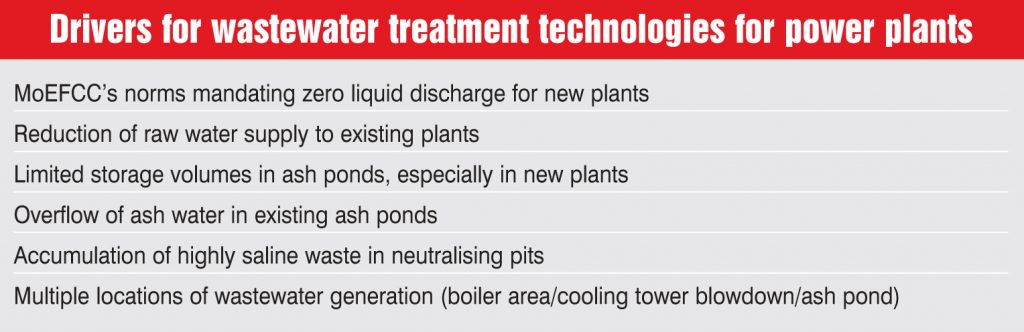

The thermal power industry is the largest contributor (80 per cent) of wastewater discharge. The treatment and disposal of wastewater is crucial as it eventually gets mixed with groundwater or surface water, thus affecting the aquatic ecosystem and environment. Wastewater as well as other liquid effluents discharged from power generation plants are among the key causes of pollution in water resources. Taking cognisance of this, the Ministry of Environment, Forest and Climate Change (MoEFCC) has tightened its water usage norms for thermal power plants. As per the new norms, plants installed after January 1, 2017 are required to meet the water consumption limit of 2.5 cubic metres per kWh and achieve zero liquid discharge (ZLD). Power plant owners, therefore, need to recycle wastewater. Moreover, in the revised Tariff Policy, 2016, power plants located within a radius of 50 km from a sewage treatment plant (STP) have been mandated to use treated sewage water.

Besides environmental benefits, wastewater treatment and ZLD systems provide a range of benefits for power plant operators/generation utilities. Power plants with ZLD from the design stage are likely to gain public acceptance and obtain statutory approvals smoothly, which is otherwise a tedious and time-consuming process. Further, wastewater recycling provides more options for site selection to generation companies as the concerns regarding adequate water supply are mitigated to quite an extent. In addition, wastewater recycling significantly reduces the amount of make-up water that the genco may need to purchase from the state water boards. It also eliminates the costs associated with sewer disposal.

Wastewater treatment technologies are useful for treating not only the discharged water from power plants, but also the water that is fed into the plant. For instance, the quality of raw water at some of NTPC’s plants is quite poor, almost like diluted sewage water. This can cause many operational problems such as fouling and corrosion of condenser tubes, poor quality of demineralisation water and increase in boiler tube leakages. Therefore, NTPC’s research wing, NTPC Energy Technology Research Alliance, is working towards the development of wastewater treatment technologies at plant sites and optimisation of effluent treatment plants’ operations.

Wastewater treatment options

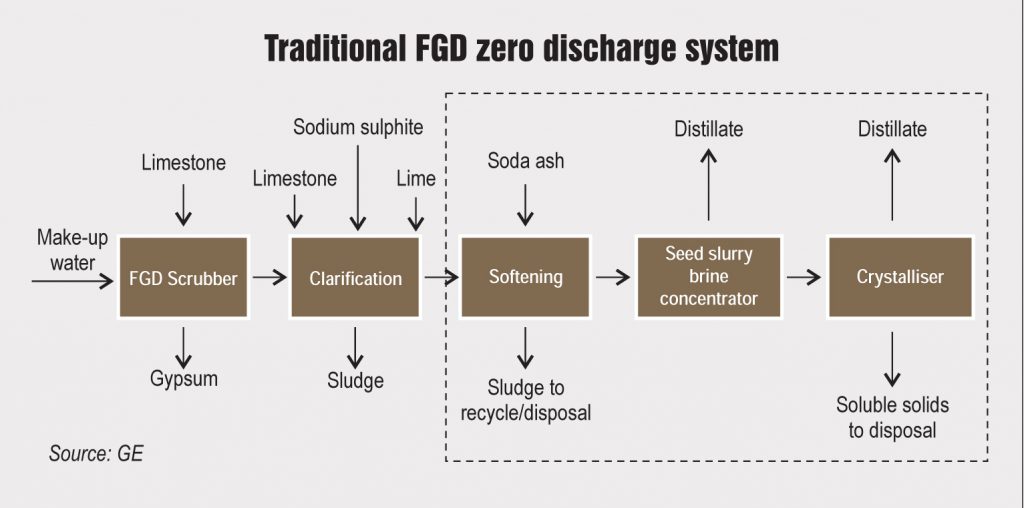

There are several sources of wastewater in power plants such as cooling tower blowdown and wet flue gas desulphurisation (FGD) systems. The wastewater so produced contains salts such as sodium sulphate, sodium chloride, calcium, magnesium and bicarbonates. Typically, effluent treatment plants comprising evaporators, crystallisers and dewatering units are installed at power plants to remove these salts and produce clean water that can be recycled into the plant.

The cooling tower blowdown is often highly saturated with calcium sulphate and silica and it is tough to separate these salts through evaporation as wastewater is already at the scaling point. Therefore, methods have been adopted wherein calcium sulphate seeds are added to the saturated wastewater to suspend these precipitating salts. A seed slurry brine concentrator deploys the same principle. Seeded slurry technology allows concentration without scaling of surfaces and reduces the volume of wastes. It is ideal for waste streams with high levels of total dissolved solids.

Meanwhile, wastewater from wet FGD systems is difficult to crystallise by evaporation as it contains soluble salts such as calcium and ammonium chlorides as well as heavy metal salts. This kind of wastewater requires pretreatment with chemicals so that a crystalline solid can be produced. For pretreatment, wastewater is directed into reactor tanks, where chemicals such as caustic soda/ lime and sodium sulphide/organosulphide are added to precipitate heavy metal ions as insoluble hydroxide and sulphide salts. Subsequently, ferric chloride/alum and certain polymers are added to coagulate the precipitates and form large flocs, which settle at the bottom of a clarifier and are filtered later. Though this method is well suited to reduce the suspended solids, metals and acidity in the wastewater, it is ineffective in filtering the soluble salts, including calcium, magnesium, sodium and ammonium combined with chloride and nitrate, as well as any organic compounds. These are later removed using biological treatment.

As the norms for discharging wastewater are becoming more stringent, more treatment methods may be required to reduce concentrations of some chemicals such as mercury and selenium to the part per trillion levels. In such cases, membrane-based technologies such as reverse osmosis (RO) are used to recover water in ZLD systems. However, it must be noted that the deployment of pretreatment and membrane technologies results in increased capex and opex of the ZLD plant as they deploy a variety of sophisticated equipment and chemicals.

Optimisation strategies

The effluent treatment plant should be designed taking into account the cooling tower blowdown and neutralised regeneration wastes from the demineralisation plant. Power plant operators can also optimise the capacity and cost of the effluent treatment plant by making some changes to its day-to-day operations. Operators can divert the final rinse water of ion exchange beds directly to the cooling tower make-up water chamber. They can also provide lamella/tube settlers in the boiler area for reuse in bottom ash handling and fly ash dust suppression. Further, the boiler blowdown can be led to the cooling tower make-up water chamber.

A well-designed effluent treatment plant can help achieve recycling and reuse of cooling tower blowdown. However, this requires implementation of a high recovery RO plant from suppliers having a proven track record. The ZLD system comprising evaporators and crystallisers, when integrated with the purchase of the high recovery RO plant, will be more cost effective. In addition, the build quality, material selection, availability and plant life of ZLD systems must be taken into account while choosing the system. Further, it is possible to optimise an effluent treatment plant’s capacity by implementing process changes to reuse wastewater streams with minimal or no treatment.

The way forward

With the MoEFCC’s new water usage norms, power plants now need to be designed from the ground up with ZLD systems in place. Although ZLD has become popular in India in recent years, such systems have been in operation in developed countries including the US since the mid-1970s. Domestic utilities and equipment suppliers must therefore take steps to share technology and gain experience in the implementation of ZLD systems from international markets. In addition, policymakers should mandate third-party water audit of power plants to ensure that efficient water consumption practices are followed by the operators going forward.

The power ministry has also reportedly mapped the operational STPs in cities that are at a maximum distance of 50 km from the power plant, and has identified 29 power plants across the country, which could be supplied with treated water from STPs.

NTPC has taken a lead role in this regard and has identified five power stations – Solapur, Mouda, Meja, Dadri, and the upcoming Patratu plant for the use of sewage water to cater to the make-up water requirement of its thermal power plants. For the Solapur plant, it has already signed a binding agreement with the Solapur Municipal Corporation. It is actively negotiating with other municipal corporations in the respective states. Among the state gencos, Maharashtra State Power Generation Company Limited has tied up with the Nagpur Municipal Corporation for its Koradi power station.

However, if the water provided by the state is not of the desired quality, power plant developers may need to deploy tertiary wastewater treatment plants, resulting in additional investments. These investments have, however, been made pass-through in the Tariff Policy. Also, as the quantity of sewage generation will vary every day, power producers may need to invest in storage facilities to maintain a uniform supply round the day.

Net, net, wastewater treatment and ZLD technologies are expected to witness an upsurge in demand in the near future.

With inputs from a presentation by Himanshu Gupta, Sales Director, South Asia, GE Water