Hydropower is set to play a key role in the transition to renewable energy, given its ability to address the intermittency and grid balancing requirements. As the largest and most readily available source of flexibility with unmatched storage capabilities, hydropower faces a major challenge – an ageing fleet in the country that is prone to structural issues. To overcome these issues, developers are implementing asset management and strategic operations and maintenance (O&M) practices to prevent plant outages and ensure optimal power generation. These older hydro projects are located in Himachal Pradesh, Uttarakhand and Arunachal Pradesh, which are also geologically and climatically vulnerable regions.

Proper O&M of hydropower plants provides benefits such as improved efficiency and output, enhanced dam safety, reduced cost and frequency of repairs, and increased longevity of the plant. Developing a strategic O&M practice for an existing hydropower plant only represents a small percentage of the cost of electricity generation, but saves significant expenses in the long run, leading to increased return on investment. The key areas of focus for O&M include surveillance and inspection, instrumentation, and emergency action planning.

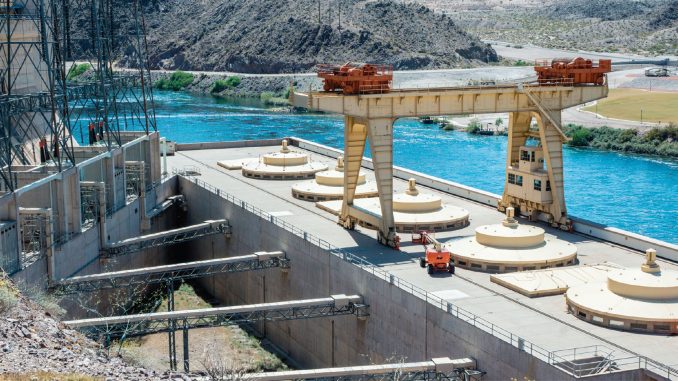

Surveillance and inspection

The Dam Safety Act, 2021, formulated in December 2021, provides for the surveillance, inspection and O&M of specified dams to prevent dam failure-related disasters and ensure the safe functioning of dams. Under the act, owners of specified dams are required to provide a dam safety unit, prepare an emergency action plan, carry out risk assessment studies, and undertake comprehensive dam safety evaluation at regular intervals. At hydroelectric plants, periodic dam safety inspections, both pre- and post-monsoon, are undertaken as per the Central Water Commission (CWC) guidelines. Meanwhile, the dam safety inspection guidelines cover an overview of dam inspection, a dam safety inspection programme, inspection of embankment/concrete/masonry dams, spillway outlets, mechanical equipment and general areas, visual inspection, use of remotely operated vehicles and unmanned aerial vehicles, documentation, and a comprehensive dam safety review by a panel of experts.

The emergency action plan (EAP) defines the unusual and unlikely conditions that may endanger dams. It aims to minimise damage to property, structures and inhabitations, as well as reduce environmental impacts in the event of flood caused by large releases, or dam failure. The EAP is prepared as per the CWC guidelines. Developing an early warning system (EWS), especially in hilly regions, is essential to prevent losses caused by disasters. NHPC Limited has implemented EWS in nearly every project. Further, NHPC has established a master control room equipped with advanced software and technologies at its Faridabad office with 24×7 real-time monitoring and alert generation mechanisms that cater to all vulnerable projects. It has also launched a software called eAABHAS for this purpose.

O&M

As part of O&M works, the preparation of comprehensive reports along with an action plan for repair and rehabilitation (R&R) is undertaken. It is followed by monthly monitoring of identified repair works, comprehensive dam safety review by an independent panel of experts, and submission of report and compliance.

There is a standard operating procedure for the sudden release of water from the dam to downstream areas. It involves identifying, planning, implementing and monitoring safety measures for people living in downstream areas in the event of a sudden release of water from the dam.

Some of the O&M practices that developers can adopt include operational analysis of all plants on a daily basis, tripping and breakdown analysis, technical inspection and dam safety inspection, among others. Insights from these evaluations can help in the adoption of preventive maintenance schedules, replacement of equipment, inventory optimisation, training of O&M staff and optimising afforestation in catchment area. Furthermore, the O&M needs of hydropower plants developed in the Himalayan region primarily focus on mitigating the challenges posed by sediment in the inflow. Hydro abrasive erosion is a common damage suffered by many NHPC plants, such as Salal Dulhasti, Chamera-II, Dhauliganga, Teesta-V and Baira Siul, which are situated on rivers that carry excessive hard particles such as quartz, mica, feldspar and muscovite. These hard particles flow with high velocity and damage the underwater components of hydro turbines. An efficient sediment management system can help protect the economic and useful life of the reservoirs. Efforts are made to avoid or delay abrasion by using material that match the hardness of quartz particles. Additionally, the underwater parts are coated with HP HVOF coating to mitigate abrasion and erosion.

For the operational analysis of all plants, the inflow, water utilisation, reservoir level, spillage, and other operational parameters are monitored on a daily basis. The restricted governor mode of operation has been implemented at six power stations, automatic generation control AGC has been implemented at 11 power stations, and mock black-start exercises are being carried out by power stations as per schedule and procedures given by the regional load despatch centres. Meanwhile, tripping and breakdown analysis is carried out for each event to identify the root cause of fault for early restoration. Further, monitoring the health and maintenance of civil structures at power stations is considered equally important in the overall performance of the power stations. For this, the technical inspection of all power plants is conducted by the O&M team and dam safety inspections are conducted by the design and engineering team.

The performance of hydropower stations is often impacted by the non-availability of critical spares. The remote location of hydropower plants further aggravates the problem. For this, NHPC identifies the critical spares needed for each power station along with the minimum and maximum inventory. Each power station maintains a minimum critical inventory level. The initiation of purchase, award and delivery of spare parts is monitored to ensure availability of critical spares to carry out annual capital maintenance as per schedule and to meet any exigencies. Further, preventive/annual maintenance schedules are framed based on history, operational aspects, technical inspection and the recommendation of original equipment manufacturers. There is an added emphasis on the replacement of major underwater parts, which is a less time-consuming method than the repair and reuse method. This strategy effectively reduces the maintenance period and increases the operational availability of the plant.

Repair and rehabilitation

Rehabilitation of a dam is the act of restoring the distressed dam to its original state and also improving it to meet the changing safety criteria and related requirements. NHPC is utilising the latest available technologies while simultaneously ensuring the uniformity of practices. It has standardised its methodologies, and adheres to technical specifications as per the stipulated guidelines for R&R. The company has also adopted best practices for R&R in line with the national and international standards, and is undertaking innovations to improve the R&R procedures for maximum benefits and improved safety. Quality tests are conducted to ensure the quality of work. It is important to ensure the assessment of the functional requirements of the various components of power stations. Moreover, the use of appropriate material with standardised performance characteristics can optimise the cost and frequency of repair and enhance plant safety.

Early R&R of civil structures is essential for continued and reliable operation of these valuable assets. Uniformity in processes adopted for repair and maintenance across locations will help in early detection and recognition of deviations and deficiencies. Further, R&R is important to achieve structural integrity and address safety concerns. During the monsoons, the Himalayan rivers carry a large quantity of sediment along with boulders over the spillway, causing frequent damages in dam spillways, stilling basin and other critical areas. Other components also get damaged due to ageing, hydraulic forces and various other reasons.

The regular periodic inspection of completed and operating hydraulic structures is extremely important. It helps in identifying structural cracking, spalling and surface irregularities, and determining the extent of damage. Further, the condition of concrete is assessed by non-destructive testing or core drilling and sampling if required. Existing and potential problems are identified and categorised as minor, major or potentially catastrophic. The scope of work and the repair methodologies should be identified beforehand in view of the limited time period for undertaking repair works. A quality assurance and monitoring system should be in place for the timely completion of work.

A number of construction materials including high performance concrete, standard concrete, cementitious mortar, epoxy compounds, crystalline material, and steel liner are available to repair the damages. Cementitious mortar is used for structural repair and for repair of cracks and voids; epoxy mortar is used for the repair of concrete and epoxy grout for repair of cracks; and crystalline material finds applications in repair and waterproofing with slurry or in sealing cracks and construction joints with mortar.

For the rehabilitation of large dams, CWC launched the Dam Rehabilitation and Implementation Project (DRIP) with assistance from the World Bank in 2012 with an objective to improve the safety and operational performance of selected dams with an institutional support system-wide management approach. Constructing a new dam is very challenging due to factors such as population density and intensive land use. The safe operation of dams and reservoirs through the latest safety concepts is the need of the hour for dam safety management. Further, the manual released by CWC for rehabilitation of large dams in January 2018 provides an overview of dam rehabilitation, planning, field investigation, material, concrete and masonry dams, embankment dams, and appurtenant works.

The renovation, modernisation and up-gradation is also undertaken due to ageing, deterioration and damage. This involves technological upgradation and experience-based modification in the components for optimal benefit and safety; innovations aimed at increasing efficiency; modifications based on updated hydrological, geological and seismic studies for safety. NHPC has completed the renovation and modernisation (R&M) of the Baira Siul power station and undertaken the R&M of the Loktak power station.

Digital initiatives

Digital systems like SCADA, digital governor and excitation systems provide stability for set values, flexibility in design and reduced wiring. Microprocessors enable faster machine response in digital control systems with the use of faster sampling rates. Digital systems also help in better implementation of grid requirements. Currently, 18 power stations of NHPC are automated and equipped with the SCADA system for plant operation. Automation of the remaining two power stations has been taken up in phases. Furthermore, many of the NHPC power stations are now equipped with digital governor and excitation systems.

The way ahead

Recent policy measures have spurred growth in the hydropower sector. However, any of this cannot compensate for the lack of or poorly designed O&M practices. Good O&M practices will not only improve the health of assets and their reliability, but also save the country from the exorbitant expenses of building new hydro plants, numerous environmental risks, and the pain of relocation and rehabilitation of people. The digitalisation of hydropower plants can aid asset management. Condition-based monitoring and predictive maintenance of hydropower systems are other solutions that can yield immediate savings in maintenance costs.

Adopting O&M best practices and asset management strategies can optimise the performance of hydro power stations in an increasingly cost-driven market and stringent regulatory framework. Therefore, utilities must adopt emerging technologies and undertake innovative approaches in the future.

Based on presentations by Sandeep Batra, General Manager (Planning), and Suraj Dhiman, General Manager (O&M), NHPC Limited, at a recent Power Line conference