Gujarat’s state transmission company, Gujarat Energy Transmission Corporation Limited (GETCO) has drawn up a comprehensive plan for modernising and augmenting its infrastructure over the next four years. Investments in transmission are driven by the need to meet the increasing power load, modernise ageing and obsolete assets as well as accommodate the upcoming generation capacity including variable renewable energy capacity. The transmission company plans to invest over Rs 11 billion until 2021 to add 80-100 substations and 2,800 ckt. km of lines annually.

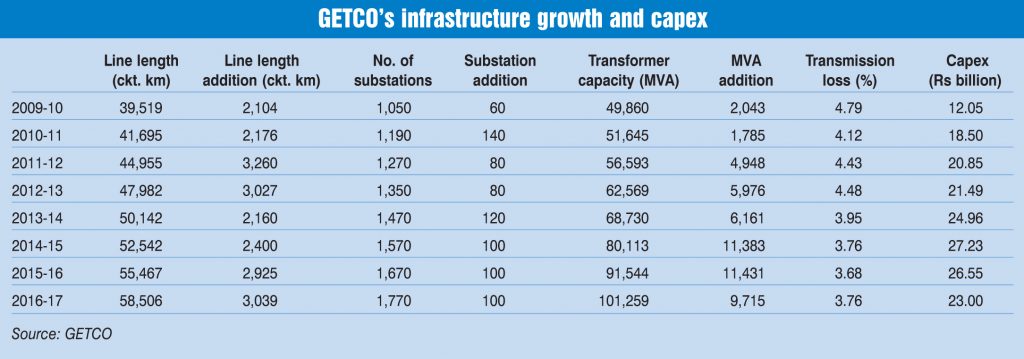

The company’s expansion plans are in continuation of the strides it took in terms of infrastructure growth in 2010, when the substation addition increased to an average of 100 from 50-60 substations and line length addition increased to 2,700 ckt. km from about 1,000 ckt. km. “We have planned the capex in a way that today the transmission network can handle a peak load of 26 GW as against the actual of 16 GW,” says B.B. Chauhan, managing director, GETCO.

Existing infrastructure

GETCO’s transmission assets include 58,506 ckt. km of lines, 1,770 substations and 101,259 MVA of transformer capacity as of March 31, 2017. Over 90 per cent or 1,600 substations are at the 66 kV level, around 100 substations are at the 220 kV level, 56 substations at the 132 kV level and 14 substations at the 400 kV level. The majority of transmission lines are also at the 66 kV level. Owing to proper maintenance of assets, GETCO managed to achieve transmission line and substation availability of over 99.5 per cent and 99.8 per cent respectively over the past five years. The company’s transmission losses have remained under 4 per cent since 2013-14 and stood at 3.76 per cent in 2016-17.

The asset mapping of GETCO’s transmission network indicates that 34 per cent of substations and 31 per cent of lines are over 20 years old. In order to improve asset management, GETCO has been undertaking equipment health assessment and renovation and modernisation (R&M) activities.

Key initiatives

The transmission company has been undertaking various initiatives in infrastructure development. According to Chauhan, “Some of our key initiatives have been identifying potential load pockets, replacing ageing and obsolete assets, integrating renewables coming up at remote locations, deploying state-of-the-art technologies, and undertaking integration of asset management process.”

R&M

Given that nearly one-third of GETCO’s infrastructure is ageing, it has moved from periodic preventive maintenance to condition monitoring, both offline and online, with the deployment of state-of-the-art testing equipment. GETCO invested Rs 9 billion and Rs 10 billion in R&M activities during the Eleventh and Twelfth Plan periods respectively.

It has undertaken several other measures to improve the operational efficiency of its existing assets. These included R&M of aged and old conductors, insulators, towers in coastal and chemically polluted areas, replacement with polymer insulators, equipment replacement to overcome limitation of short circuit level, improving sluggish and unreliable electromagnetic and static relays, double bus conversion in substations having outdated single bus arrangement, augmentation of bus and transformation capacity to handle load growth. “Since five years we have been deploying only polymer insulators and have stopped using porcelain insulators, which cause unwanted tripping in the coastal belt”, informs Chauhan.

Efficiency improvements

GETCO has fully implemented the n-1 redundancy criterion for all substations, which helped it achieve higher load handling capacity than the actual load. This redundancy has been achieved for around 80 per cent of the lines. With about 5,000 MVAr of reactive power capacity already installed, GETCO has been able to reduce transmission losses and improve the quality of power supply. It has been optimising its distribution feeder length and substation location to overcome load diversity between agricultural and urban loads.

It has standardised design and drawings to save engineering time. The company undertakes hotline maintenance using live line washing machine, which has been designed in-house and certified by the National Power Training Institute and the Electrical Research and Development Association.

GETCO is upgrading its existing substations by utilising the available land. This results in huge savings in terms of time and money as well as timely creation of assets at the load centre when required. However, challenges related to system reliability, safety, outages and sudden equipment failure have to be considered to ensure best results. Further, the company has been fully utilising the existing corridors by upgrading to multi-circuit lines.

GETCO has put in place a separate state transmission utility cell, which undertakes network review on a half-yearly basis and grid performance review on an annual basis.

Adoption of new technologies

GETCO is among the progressive state transmission companies and focuses on research and development to be up to date on the technology front. It has technical collaborations with institutions like IITs and NITs to find solutions to grid operation issues and for the optimum utilisation of transmission infrastructure. The company also has a vendor development policy in place, which encourages testing and adoption of new technologies on its network. To ensure transparency and competition, the complete process of material procurement and inspection is carried out through an online portal.

GETCO has also been adopting several smart grid technologies. It has automated 10 substations through the conversion of a conventional protection system into a substation automation system. It plans to automate 10 more substations. In a bid to improve reliability and availability, the company intends to deploy digital substations. As a first step, it has deployed optical current transformers and merging units in existing substations. GETCO completed two pilots involving the installation of 220 kV optical current transformers (CTs) at the Jambuva and Lunawada substations and one pilot involving the installation of an analog merging unit and intelligent control unit for circuit breaker and isolators in one line bay at the 400 kV Asoj substation.

Further, GETCO has been deploying gas-insulated switchgear (GIS) and hybrid switchgear as they are maintenance-free and economical on a life-cycle-cost basis. Two 66 kV GIS have been installed at the Shastri Maidan and Lal Bunglow substations, one 220 kV GIS at the Atul substation and two 220 kV hybrid switchgear at the Sartanpar and Suwa substations. The company is upgrading its existing substations to higher voltage with GIS/hybrid technology by utilising the spare land in existing complexes. For instance, the 66 kV Santej substation has been upgraded to 220 kV with hybrid switchgear.

The transco is increasingly adopting high capacity conductors and high temperature low sag conductors, as they have 50 per cent more capacity with less transmission loss. It has permanently adopted AL59 alloy conductors for the 220 kV voltage level. The company no longer uses aluminium conductor composite reinforced for 220 kV and 400 kV voltages.

It has successfully adopted power transformers with ester oil in the 66/11 kV class as this oil has a high flashpoint to safeguard transformers from catching fire. The company is also undertaking pilots for the 220 kV and 400 kV voltage levels. GETCO has implemented integrated asset management system and transmission asset management system, which is a centrally managed enterprise resource planning solution. This system flags abnormal figures and helps in centralised monitoring. It has also deployed geographic information system for better network planning and asset management.

Given the growing importance of communication for remote control and monitoring, GETCO has been laying optical ground wire (OPGW) and replacing conventional power line carrier communication with fibre optic terminal equipment. So far, 710 km of OPGW, which ensures bigger bandwidth for data communication, has been laid and 20 substations have been connected and commissioned. Chauhan confirms that no earthwire has been laid since the past five years. GETCO plans to upgrade ten 400 kV and 220 kV existing substations from conventional mode to supervisory control and data acquisition (SCADA) mode in the first stage and subsequently operate them from the remote centre with the help of OPGW.

Some of the technologies under implementation are a fully digital substation with process bus (220/66 kV Sevalia substation), line monitoring unit to assess maximum line capacity, fault current limiter to reduce fault current without affecting power system stability and reliability, SF6 switchgear with SCADA at 11 kV to optimise the manpower for operations, and STATCOM (static synchronous compensator) for dynamic reactive power.

Finances and investments

GETCO is a profitable company. Its revenue increased by about 5 per cent to Rs 26.94 billion in 2015-16 from Rs 25.7 billion in the previous year. The company’s expenses increased by 10 per cent to Rs 23.9 billion. However, profits declined by about 35 per cent to Rs 1,886 million as compared to Rs 2,886 million in 2014-15. GETCO’s net worth increased by over 13 per cent to Rs 58.7 billion from Rs 51.8 billion. The return on equity at 14 per cent was Rs 6 billion for 2015-16 as approved by the Gujarat Electricity Regulatory Commission (GERC).

The company has made huge investments in its transmission network from 2010 onwards. Its capex almost doubled to Rs 12.3 billion during the Twelfth Plan period from Rs 6.4 billion in the Eleventh Plan period.

Going forward, capex of over Rs 101 billion has been planned for the period 2017-18 to 2020-21 translating into approximately Rs 25 billion annually. The company plans to fund this investment at 70:30 debt-equity. During this period, 11,241 ckt. km of transmission lines and 340 new substations have been proposed to be added. The majority of future investments will be made at the 66 kV level as well as high voltage network development to integrate renewable energy. GERC-approved aggregate revenue requirement (ARR) for the period is Rs 158 billion.

In addition, Rs 2.5 billion will be invested annually in R&M until 2020-21. Besides, the majority of R&M investments will be made in transmission lines at 44 per cent, followed by the replacement of obsolete assets (26 per cent), substation renovation (17 per cent), civil renovation (8 per cent) and protection system (5 per cent).

Challenges and the way forward

Like its counterparts, GETCO also faces challenges associated with land acquisition and statutory clearances for forest, railways and highways. “There is proper coordination at the central level and we are getting clearances on time. However, issues exist in limited pockets where extensive follow-up is required. Normally, we acquire only government land but there are constraints due to restrictions imposed on gauchar (grazing) land,” says Chauhan. GETCO has set up a separate land acquisition cell to coordinate with the state government.

Other problems faced by GETCO include delay in the construction of transmission lines due to right-of-way issues, limited skilled agencies, grid operation constraints associated with renewable energy and the need for storage. “Variation of 1,000-1,200 MW renewable energy generation and 2,000 MW variation in demand in a day is quite common. Such variations in the system are persistent and can be handled continuously by regulating generation and optimising the operation of lines, inter connecting transformers (ICTs) and shunt elements,” says Chauhan.

GETCO is focused on long-term planning and has been coordinating with the discoms to meet their load requirements. It has also been monitoring the new generation including renewable energy that has come up in the state. Given the changing generation landscape, GETCO is geared up for exciting times ahead.

Swarna Kesavan